In today’s fast-paced world, industries are constantly dealing with hazardous materials that, if not managed properly, can lead to serious environmental and health risks. One effective way to control and manage spills is through the use of hazmat booms. These specialized tools are essential for containing and absorbing spills, ensuring that any hazardous substances are quickly and efficiently managed to minimize damage.

In this article, we will explore the different types of hazmat booms available on the market and guide you in choosing the right solution for your specific spill response needs.

Understanding Hazmat Booms

Hazmat booms, also known as absorbent booms, are cylindrical tools that are designed to contain and absorb hazardous materials. They are used in a variety of settings, including industrial sites, waterways, and transportation routes, to prevent the spread of harmful substances. These booms are an integral part of any spill response plan, providing a first line of defense against potential disasters.

Why Use Hazmat Booms?

The primary purpose of hazmat booms is to contain spills and prevent them from spreading to uncontaminated areas. By acting as a barrier, they help protect the environment and human health by reducing the risk of exposure to dangerous substances. Additionally, using hazmat booms can simplify the cleanup process, making it easier and more efficient to manage spills.

Types of Hazmat Booms

There are several types of hazmat booms available, each designed to handle specific types of spills. Understanding the differences between these booms will help you select the right one for your needs.

Oil Spill Booms

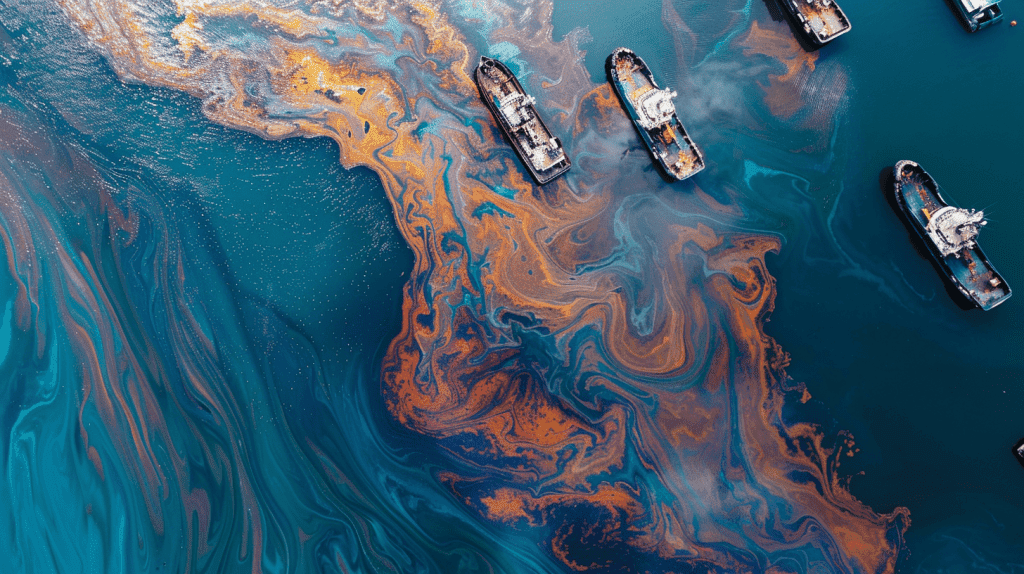

Oil spill booms are specifically designed to contain and absorb oil spills on water surfaces. These booms are typically made from materials that repel water while attracting and absorbing oil. This makes them particularly effective for marine environments, where oil spills pose a significant threat to aquatic life and ecosystems.

Features of Oil Spill Booms

- Hydrophobic Materials: Oil spill booms are made from hydrophobic materials, which means they repel water while effectively absorbing oil.

- Durability: These booms are built to withstand harsh marine conditions, ensuring they remain effective even in challenging environments.

- Ease of Use: Oil spill booms are easy to deploy and retrieve, allowing for quick response to oil spills.

Universal Absorbent Booms

Universal absorbent booms are versatile tools that can handle a wide range of spills, including oils, coolants, solvents, and water-based liquids. They are ideal for industrial settings where different types of spills may occur.

Features of Universal Absorbent Booms

- Versatility: These booms can absorb a variety of substances, making them suitable for diverse industrial applications.

- High Absorbency: Universal absorbent booms are designed to absorb large quantities of liquid, ensuring effective spill containment.

- Cost-Effective: These booms offer a cost-effective solution for managing various types of spills.

Chemical Absorbent Booms

Chemical absorbent booms are engineered to handle hazardous chemical spills. They are made from materials that can safely absorb and contain aggressive chemicals, ensuring the safety of personnel and the environment.

Features of Chemical Absorbent Booms

- Chemical Resistance: These booms are resistant to a wide range of chemicals, including acids and bases.

- Safety: Chemical absorbent booms help protect workers by minimizing exposure to hazardous substances.

- Compliance: Using chemical absorbent booms helps ensure compliance with safety regulations and environmental standards.

Choosing the Right Hazmat Boom

Selecting the right hazmat boom for your spill response needs involves considering several factors:

Type of Spill

The first step in choosing the right boom is to identify the type of spill you are dealing with. Consider the substance involved, its properties, and the environment in which the spill has occurred. This will help you determine whether you need an oil spill boom, a universal absorbent boom, or a chemical absorbent boom.

Environment

The environment in which the spill occurs is another critical factor to consider. For spills on water, oil spill booms are the ideal choice. However, for spills in industrial settings, universal or chemical absorbent booms may be more appropriate.

Quantity of Spill

The volume of the spill is also important when selecting a hazmat boom. Ensure that the boom you choose has the capacity to absorb the entire spill, preventing any overflow or further contamination.

Compliance and Safety

Finally, consider any regulatory requirements or safety standards that apply to your specific situation. Using the appropriate hazmat boom can help ensure compliance with these regulations and protect both workers and the environment.

Conclusion

Hazmat booms are an essential component of any spill response plan, providing an effective means of containing and absorbing hazardous materials. By understanding the different types of hazmat booms available and considering factors such as the type of spill, environment, and regulatory requirements, you can select the right solution for your needs.

Investing in the appropriate hazmat booms not only helps protect the environment and human health but also simplifies the cleanup process, ensuring a quick and efficient response to spills. Always be prepared with the right tools to tackle any spill situation that may arise, and keep your operations safe and compliant.

Call to Action

When it comes to protecting your environment and ensuring quick spill response, trust Absorbents Online for all your hazmat boom needs. With a wide array of products specifically designed to tackle any spill, Absorbents Online offers the reliability and quality you need to keep your operations safe and efficient. Shop now and equip your spill response team with the best tools available. Visit Absorbents Online today to explore our comprehensive selection and find the perfect hazmat boom solutions for your facility.