Explore Best Practices for Storing and Handling Flammables at Work

Did you know improper storage and handling of flammable liquids are significant contributors to industrial fires? According to research by the National Fire Protection Association (NFPA), United States fire departments respond to over 36,000 industrial fires annually. These fires result in substantial losses, including property damage, equipment loss, injuries, and even fatalities. The U.S. Fire Administration estimates nonresidential building fires cost over $3.6 billion in 2021 alone.

Did you know improper storage and handling of flammable liquids are significant contributors to industrial fires? According to research by the National Fire Protection Association (NFPA), United States fire departments respond to over 36,000 industrial fires annually. These fires result in substantial losses, including property damage, equipment loss, injuries, and even fatalities. The U.S. Fire Administration estimates nonresidential building fires cost over $3.6 billion in 2021 alone.

Given that flammable liquids are common in almost every industry, understanding how to safely store and work with them is paramount. Read on to discover how you can help mitigate industrial fire risks in your workplace.

Understanding the risks of flammables

Flammable materials pose a serious fire hazard due to their ability to ignite and sustain combustion. The most common flammable substances typically found in industrial settings include fuels, solvents, chemicals, and gases.

Ways to avoid an industrial fire

If you don’t want to play host to an industrial fire, you need to follow some important best practices while handling chemicals.

- Know your liquids. Read the safety data sheet (SDS) for each flammable liquid before you work with it. You should know how to safely clean up any liquid you use.

- Limit and reduce. When possible, substitute flammable liquids with non-flammable or less-flammable liquid alternatives. You may also want to reduce the quantity you use; you should only be using as much liquid as is necessary. When a liquid is not in use, keep its container closed.

- Monitor possible sources of ignition. Control all ignition sources in any area where a flammable liquid is being used. Never heat flammable substances over an open flame — instead, use oil, steam, water or hot air baths, or heating mantles. Also, ensure that any metal surfaces are properly grounded to safely discharge static electricity and prevent sparks.

- Take safety precautions. Always wear personal protective equipment that is appropriate for the materials you are working with. Use a chemical fume hood when working with flammable liquids, and know the locations of emergency equipment such as fire alarms, pull stations, fire extinguishers, and safety showers.

Safely store your flammables and chemicals

Of course, these best practices above are all recommended while you’re working with liquids. What about when flammable chemicals are being stored?

For small quantities of individual chemicals, use approved containers such as metal safety cans that are specifically designed for housing flammable liquids.

To keep all your flammable liquids contained safely between uses, store them in rated flammable storage or explosion-safe cabinets. If possible, these cabinets should not be vented. Storage units must be properly labeled as flammable, either with the words “Flammable — Keep Fire Away” or with a red flammable diamond sticker.

Avoid storing flammable liquids on floors, near ignition sources (such as electrical outlets or hot surfaces), or in quantities greater than 55 gallons. And of course, flammable liquids should be stored separately from strong oxidizers, corrosives, and other incompatible materials.

A lowdown on safety storage cabinets

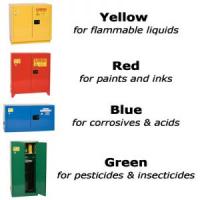

Whether it’s paint, pesticides, or acids, we have an OSHA-compliant safety cabinet to suit your needs. They are also National Fire Protection Association (NFPA) compliant, too.

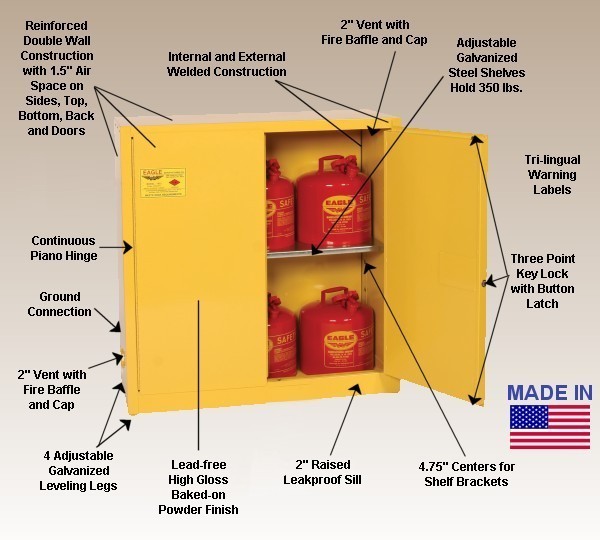

Each of these cabinets is double-walled with 1.5 inches of air space between the walls. The cabinets are made of 18-gauge steel and high-density polyethylene. Vents include 2-inch threaded fittings, fire baffle, and cap.

Cabinets also come with a grounding attachment, three-point key lock, and a 2-inch, raised, leak-proof spill door. Adjustable shelves, supported by four brackets, can hold up to 350 pounds. Here’s a quick primer on the main features and different types of storage cabinets:

Flammable Liquid Storage

Styles of flammable storage safety cabinets include tower, stackable, under-counter, wall-mount, or regular floor cabinets. These yellow cabinets are available in sizes from 4 to 90 gallons and with manual or self-closing doors.

Paint & Ink Safety Cabinets

Available in red and yellow, these chemical cabinets store 30-96 gallons of paint or inks. They feature doors that either close automatically or manually.

Acid & Corrosive Cabinets

These acid storage models are corrosion-resistant and powder coated, and come with self-closing or manual doors. Steel versions have a blue finish, and polyethylene models also come in white.

Drum Safety Cabinets

Drum cabinets come in regular and hazmat steel models. They are yellow in color and available in 55-, 60-, and 110-gallon capacities.

Pesticide Safety Cabinets

Green color pesticide cabinets come in steel and polyethylene versions. They are designed for optimal segregation of insecticides, herbicides, and fungicides.

Protect Your Facility with Safety Solutions from AbsorbentsOnline.com

Don’t let your flammable liquids turn your facility into an industrial fire statistic. With education and the proper storage equipment, you can keep your workers and your facilities safe from fire.

Do you have the right flammables safety products on hand for your workplace? To find out, contact Angie Meza at angie@absorbentsonline.com or at 800-869-9633.

Do you have the right flammables safety products on hand for your workplace? To find out, contact Angie Meza at angie@absorbentsonline.com or at 800-869-9633.

This is a revision to a blog post with an original publication date of September 18, 2015.