How to Safely Clean Up Workplace Spills Containing Glass Shards

Handling workplace chemical spills is always challenging, but when you add broken glass into the mix, it becomes even more hazardous. The sharp edges of shattered glass can easily cut through skin, exposing a worker to dangerous chemicals. Plus, when it’s mixed with a chemical spill, broken glass can be hard to see.

This is why it’s important for workers to take extra caution when cleaning up spills involving glass fragments. Keep reading to learn tips and the necessary steps to handle this tricky situation safely and effectively.

Step One: Spill Containment

Some people might instinctively want to remove broken glass before dealing with the chemical spill. While this may seem like a good idea, the best approach is to immediately contain the spill so it doesn’t spread. Taking a few minutes to properly control the chemical spill will make cleanup easier, safer, and less of a hassle for everyone involved. The exact steps to containing a spill depends on the particular chemicals involved and we’ll outline some specific scenario examples later.

Booms and berms are two highly effective forms of containment for most chemical spills, including oil, flammables, corrosives, water-based, and a variety of other chemicals. One of the decisions you’ll need to make when choosing containment berms for a chemical spill is whether you want an absorbent or non-absorbent model. Just as the name suggests, absorbent berms are designed to not only contain a chemical spill, but they also absorb it. Non-absorbent berms, on the other hand, simply control and contain chemical spills so workers can clean them up more easily.

Step Two: Remove the Glass

With your chemical spill contained, you can now work on removing the glass. Make sure you are wearing heavy-duty gloves and other personal protective equipment (PPE) as necessary. Most importantly, DO NOT attempt to pick up broken glass in a chemical spill with your hands. Even with gloves, there’s always a chance of a glass shard cutting into your hand, exposing it to the potentially dangerous chemicals. So, what’s the best approach to cleaning up broken glass in a chemical spill?

Using a pair of tongs is typically the recommended method. Carefully pick up each piece of broken glass and place it into the bags or sharps container specified for your chemical spill. Do your best to get as much of the broken glass as possible. Unfortunately, it’s nearly impossible to pick up every tiny speck of glass, but gathering the large pieces will suffice.

Step Three: Absorb and Clean Up the Spilled Chemical

The third and final step is to absorb and clean up the chemical spill. With most of the broken glass out of the way, you should be able to safely clean the chemical using absorbent pads, towels, mats and similar equipment. Just remember to use extra caution, since there’s always a chance of additional broken glass shards hiding in the spill.

Step Four: Final Safety Checks

After you’ve absorbed and cleaned up the spill, it’s essential to conduct a final safety check. Ensure all contaminated materials, including used absorbents and broken glass, are properly disposed of according to OSHA’s hazardous waste regulations (OSHA 29 CFR 1910.120). Verify that the area is thoroughly cleaned and decontaminated. If there are any lingering chemical residues, use appropriate cleaning agents to remove them. Closely inspect the site for any remaining glass shards or chemical traces, ensuring the workplace is safe for everyone. Finally, document a report about the spill and follow-up with personnel safety training to help prevent future incidents.

Examples of Workplace Chemical Spills with Broken Glass

Understanding real-world scenarios can illustrate the diverse nature of chemical spills involving broken glass and highlight the importance of proper response procedures. Here are some examples:

1. Laboratory Acid Spill

In a research laboratory, a scientist accidentally knocks over a glass beaker containing concentrated sulfuric acid. The beaker shatters, and the acid spills across the lab bench and floor. Sulfuric acid is highly corrosive and poses severe risks to skin and eyes upon contact, as well as potential inhalation hazards.

Response Steps:

- Immediate evacuation and alerting of nearby personnel.

- Use of PPE including acid-resistant gloves, goggles, and lab coats.

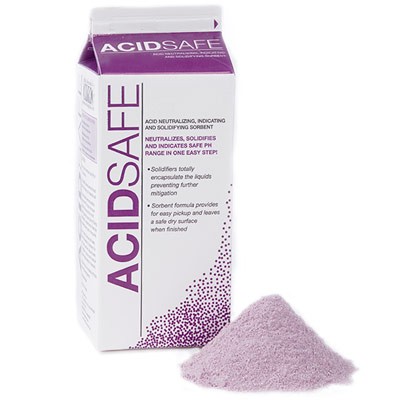

- Application of a neutralizing agent like sodium bicarbonate to the spill.

- Careful removal of glass shards using tongs and proper disposal in a sharps container.

- Cleanup of neutralized acid with absorbent pads and disposal in hazardous waste containers.

- Thorough documentation and review of the incident.

2. Industrial Solvent Spill

In a manufacturing plant, a worker drops a glass bottle of acetone while transferring it from storage to the workbench. The bottle shatters, and acetone, a highly flammable solvent, spreads across the floor.

Response Steps:

- Immediate area evacuation to prevent inhalation and fire risks.

- Alerting of emergency response teams.

- Use of PPE including solvent-resistant gloves, goggles, and respirators.

- Ventilation of the area to disperse flammable vapors.

- Containment of the spill using absorbent materials specifically designed for solvents.

- Removal of broken glass with tools and placement in a designated sharps container.

- Disposal of contaminated absorbents in a fire-resistant hazardous waste container.

- Inspection and documentation of the spill, with follow-up safety training.

3. Hospital Chemical Spill

In a hospital’s pathology lab, a technician accidentally drops a glass vial containing formaldehyde, which shatters on the floor. Formaldehyde is a toxic chemical that poses significant health risks through inhalation and skin contact.

Response Steps:

- Immediate evacuation and isolation of the area to prevent exposure.

- Notification of the spill to the hospital’s hazardous materials response team.

- Use of PPE including chemical-resistant gloves, goggles, and lab coats, with additional use of respirators.

- Use of absorbent pads and neutralizers designed for formaldehyde spills.

- Careful collection of broken glass using appropriate tools and disposal in a sharps container.

- Cleanup of the chemical with absorbent materials and placement in hazardous waste containers.

- Comprehensive documentation and a review to prevent future incidents.

4. Chemical Storage Room Spill

In a chemical storage room of a pharmaceutical company, a glass container of hydrofluoric acid (HF) falls from a shelf and breaks. HF is highly dangerous, causing severe chemical burns and systemic toxicity.

Response Steps:

- Immediate evacuation of the storage room and notification of emergency response teams.

- Ensuring the responder’s use of full-body PPE including specialized gloves, face shields, and acid-resistant suits.

- Application of a calcium gluconate gel to neutralize HF if contact with skin occurs.

- Use of absorbent materials compatible with HF to contain and absorb the spill.

- Careful handling of broken glass with non-reactive tools and disposal in a specific hazardous waste container.

- Decontamination of the area with neutralizing agents and thorough ventilation.

- Detailed incident report and medical follow-up for any exposed individuals.

5. Educational Lab Spill

In a university chemistry lab, a student accidentally breaks a glass flask containing a mixture of chemicals, including a strong oxidizer and organic solvent. The combination poses risks of chemical reactions, fire, and toxic exposure.

Response Steps:

- Immediate evacuation of the lab and alerting the lab supervisor.

- Activation of the lab’s emergency response plan.

- Donning of appropriate PPE by the response team, including gloves, goggles, lab coats, and respirators.

- Containment of the spill using absorbent materials that can handle both oxidizers and solvents.

- Removal of broken glass using forceps and placement in a designated sharps container.

- Careful segregation and disposal of the mixed chemicals as hazardous waste.

- Thorough documentation and review of lab safety protocols.

Equip Your Workplace with the Right Spill Clean up Solutions

Handling a workplace chemical spill involving broken glass requires a well-coordinated response to ensure safety and compliance. Proper training, preparedness, and adherence to safety protocols are essential in effectively managing these hazardous situations. By following the steps above, you can handle a tricky scenario to protect yourself and your coworkers from potential harm.

If you need help selecting spill containment supplies and cleanup products, reach out to AbsorbentsOnline. You can email us or call toll-free at (800) 869-9633.

This is a revision to a blog post with an original publication date of November 18, 2013.

As the winter doldrums begin to recede, spring marks a fresh start with its transition to better weather and new growth. But unfortunately, the change of season isn’t all about flowers and sunshine.

As the winter doldrums begin to recede, spring marks a fresh start with its transition to better weather and new growth. But unfortunately, the change of season isn’t all about flowers and sunshine.