What is a boom? Despite their peculiar name, booms are a highly valuable tool for containing oil spills. These versatile containment devices come in various forms that function as temporary liquid barriers. Some booms look like long, stuffed tubes while others have flat, vertical panels that act as a wall.

Booms can be used on land or water and, like other spill containment materials, come in different different types; each tailored to suit specific spill containment requirements. Booms can contain or absorb spills, guide them in specific directions, or even keep spills out of specific areas. Whatever their appearance, booms play a crucial role in minimizing the environmental impact of oil spills.

This post will provide an overview of different types of booms and some of their various use applications.

Absorbent versus non-absorbent booms

A fundamental distinction among booms lies in whether they are absorbent or non-absorbent. For instance, this oil absorbent boom not only contains a spill but facilitates its cleanup by soaking in hydrocarbon pollutants. Conversely, non-absorbent booms like this oil containment option act solely as barriers to redirect or contain fluids.

Non-absorbent booms are commonly employed to create dams while absorbent booms are utilized to skim oil from water surfaces in the event of spills. It’s also important to note that different types of booms are designed to absorb specific liquids. For example, hazardous material spills will require a hazmat absorbent boom constructed from chemical-resistant materials. Whereas oil spills require oil-absorbent booms which can repel water and therefore float on its surface. Choosing the appropriate boom depends on the nature of the spill being addressed.

A closer look at absorbent booms

Absorbent booms are further categorized based on the specific fluids they are designed to soak up. Here are two notable types:

Oil absorbent booms — The white color of these booms provides a strong contrast that makes it easy to see when they’re fully saturated with darker hydrocarbons. Because they repel water, they’ll only absorb oil and will continue to float even when fully saturated. Equipped with carbon steel connectors at each end, these booms can be easily linked together to cover large distances.

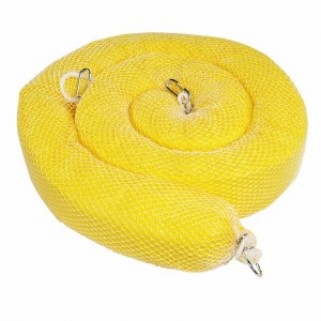

Chemical hazmat booms — With their distinctive yellow color, these booms are intended for land use, effectively containing and absorbing hazardous chemical spills. They are capable of handling various aggressive fluids, including acids, oils, and hydrocarbons, making them suitable for unknown spills as well. Quick and secure linking mechanisms enable users to create the desired length for containment.

Chemical hazmat booms — With their distinctive yellow color, these booms are intended for land use, effectively containing and absorbing hazardous chemical spills. They are capable of handling various aggressive fluids, including acids, oils, and hydrocarbons, making them suitable for unknown spills as well. Quick and secure linking mechanisms enable users to create the desired length for containment.

Close-up view: non-absorbent booms

When the primary objective is containing a pollutant rather than absorbing it, non-absorbent booms are the optimal solution. The following types of non-absorbent booms are well-suited for different water applications and circumstances.

- EconoMax — Designed for calm waters, these lightweight and cost-effective containment booms effectively block oil and debris. This model is equipped with closed-cell foam flotations, so it remains suspended in water, while a generous skirting barrier prevents pollutants from passing underneath.

- Super Swamp — These highly portable booms are ideal for shallow water use and can be easily washed and reused for extended periods, thanks to their robust construction. Available in various lengths (25, 50, and 100 feet), they cater to diverse application requirements.

- Simplex — A non-absorbent boom that is ideal to combat oil spills in marinas, harbors, and lakes. The lightweight design of the Simplex facilitates easy movement to allow boat traffic passage. These booms are UV-resistant and durable, making them suitable for years of consistent use.

- Optimax I and II — When dealing with oil spills in fast currents, the Optimax I and II are great choices. These booms feature closed-cell foam buoyancy, vinyl-coated skirting, and a top tension cable, making them well-suited for long-term deployments.

Not sure which type of booms to choose for your applications?

If you find it challenging to determine the most suitable boom type for your specific applications, remember that you don’t have to make the decision alone. Work with a partner who knows absorbents inside and out and can help you procure the exact booms required for your spill containment needs.

Contact our sales team at sales@absorbentsonline.com or (800) 869-9633 to learn more about the different types of booms. You can also visit our previous post to see a detailed component diagram and explanation of how oil containment booms work.

Conclusion

Booms are indispensable tools in the fight against oil spills, serving as temporary liquid barriers that offer containment, absorption, and redirection capabilities. By understanding the distinctions between absorbent and non-absorbent booms, as well as the various types available, you can make informed decisions to address specific spill scenarios effectively. Partnering with knowledgeable professionals will further enhance your ability to select the most suitable boom for your spill containment requirements.

This is a revision to a blog post with an original publication date of November 15, 2017