Explore polyethylene drums for safer workplace material handling

Does your business transport hazardous chemicals or waste? Whether you need to move them thousands of miles away or just from one area of your facility to another, you must ensure that the hazardous materials are transported in safe containers.

Does your business transport hazardous chemicals or waste? Whether you need to move them thousands of miles away or just from one area of your facility to another, you must ensure that the hazardous materials are transported in safe containers.

One excellent choice for this purpose is the polyethylene (poly) drum. In this guide, we’ll explore different types of poly drums and help you determine which one suits your specific needs.

Hazardous Waste Containers: A Legal Obligation

The U.S. Environmental Protection Agency (EPA) regulations mandate that businesses dealing with hazardous substances must employ containers made of materials that won’t react with the waste they hold. This ensures the safe containment of the hazardous materials.

Additionally, the U.S. Department of Transportation (DOT) requires hazardous waste containers to be clearly identified before the waste is transported. A label should indicate the type of waste in the container, including its name, characteristics, and handling requirements.

Lab Pack Drums: Ideal for Small Quantities

Lab pack drums are perfect for storing small quantities of chemicals that cannot be disposed of in the trash or down the drain. These drums are suitable for the transport of hazardous chemicals like dry cleaning compounds, strippers, pool chemicals, acids, bases, inks, degreasers, and solvents.

Constructed from blow-molded HDPE, these drums come in 14, 20 and 30-gallon capacities with two styles of lid (metal or plastic lever lock, and screw top). All lab pack drums are designed to meet DOT regulations, ensuring the safe transport of waste to a hazardous waste disposal facility.

Salvage Drums: A Must for Certain Hazardous Chemicals

Federal and state regulations necessitate the use of salvage drums for businesses that handle and transport large or small containers of certain hazardous chemicals. These chemicals include acids, bases, dry cleaning compounds, strippers, pool chemicals, inks and dyes, degreasers, paints, pesticides, solvents, and thinners.

Salvage drums serve multiple purposes: from transporting materials to storing them, holding soiled spill-cleanup materials, or serving as spill-containment or original shipping containers. They’re available in 20, 30, 65 and 95-gallon capacity with lever lock or metal band and bolt lid styles, depending on size.

Overpack Drums: Handling Spills and Soiled Absorbents

Overpack drums come in handy for storing and transporting soiled absorbents or providing spill containment for leaking or damaged containers of up to 55 gallons. They feature screw on lids with a closed-cell foam gasket that ensures a tight and secure seal.

Regulations require overpack drums for businesses with small or large containers of hazardous chemicals. They are commonly chosen by spill-containment contractors, transportation companies, labs, medical facilities, warehouses, and manufacturers.

Secure Your Workplace with the Right Poly Drums

Poly drums are indispensable tools for businesses that deal with hazardous materials. To ensure compliance and safety, it’s essential to have the appropriate poly drums on hand in your workplace.

AbsorbentsOnline has got you covered when it comes to poly drums for your hazardous materials needs. We’re here to help you make the right choices and keep your workplace safe and compliant. For any questions or assistance, feel free to contact us via email or call our toll-free number at (800) 869-9633.

We offer a wide range of options to cater to your specific requirements – see our Poly Drum Comparison Chart to find out more. Our products are designed to meet all necessary regulations and provide peace of mind in handling hazardous substances.

Be sure to also check out our previous posts, Chemical Transportation Safety and Safer Poly Drum Handling Starts with the Right Tools, to learn more.

This is a revision to a blog post with an original publication date of January 14, 2015.

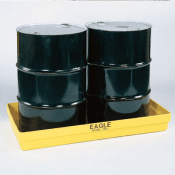

Fuel is both flammable and toxic to the environment, which is why companies need to safely store it where there’s little-to-no chance of a spill. Allowing fuel to spill or even drip in the workplace creates a dangerous scenario for nearby employees. If someone were to slip and fall on an area that’s slick with fuel, the company could be held liable for their injuries.

Fuel is both flammable and toxic to the environment, which is why companies need to safely store it where there’s little-to-no chance of a spill. Allowing fuel to spill or even drip in the workplace creates a dangerous scenario for nearby employees. If someone were to slip and fall on an area that’s slick with fuel, the company could be held liable for their injuries.