Ensuring compliance with OSHA and EPA regulations is crucial for businesses involved in handling, storing, or transporting hazardous substances. Spill containment is a significant part of these regulations, and understanding how to effectively manage spills can protect your business from legal issues and environmental harm.

In this guide, we’ll explore the essentials of spill containment, including the use of spill containment booms, railroad track pans, and oil absorbent booms, all within the framework of OSHA and EPA compliance.

Understanding Spill Containment

Spill containment involves measures and equipment designed to control, contain, and clean up hazardous substance spills. This is essential not only for environmental protection but also for the safety of employees and the community.

The Fundamentals of Spill Containment

At its core, spill containment is about preventing hazardous materials from causing harm. This involves using barriers and absorbents to manage spills promptly. The primary goal is to prevent the spread of contaminants into the environment, which could lead to severe ecological damage and health risks.

The Role of OSHA and EPA

OSHA (Occupational Safety and Health Administration) and EPA (Environmental Protection Agency) have set regulations to ensure safe handling of hazardous materials. OSHA focuses on workplace safety, while EPA emphasizes environmental protection. Together, they require businesses to have effective spill containment strategies.

Importance of Compliance

Compliance with OSHA and EPA regulations is not just a legal requirement; it is a fundamental aspect of corporate responsibility. Failure to comply can result in significant fines and legal action. Moreover, non-compliance can lead to catastrophic environmental disasters, tarnishing a company’s reputation and causing irreversible harm to ecosystems.

Key Components of Spill Containment

Let’s break down the critical components of spill containment that align with OSHA and EPA regulations.

Spill Containment Booms

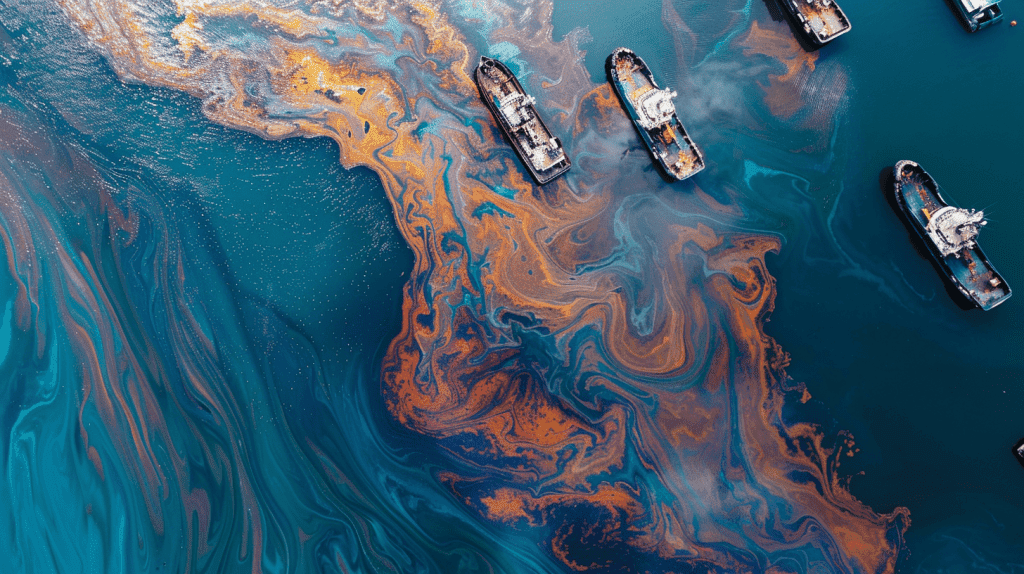

Spill containment booms are barriers designed to contain spills on water. They are crucial for preventing oil and other hazardous substances from spreading in water bodies.

Types of Spill Containment Booms

Spill containment booms come in different varieties, each serving a unique purpose. Absorbent booms are crafted to soak up oils and other liquids, effectively reducing the spill’s impact. Non-absorbent booms, on the other hand, act as physical barriers that prevent the spread of spills without absorbing the liquid.

Advantages of Using Spill Containment Booms

The primary advantage of using spill containment booms is their ability to localize a spill, allowing for easier and more effective cleanup. This is particularly important in aquatic environments where the spread of pollutants can have widespread and devastating effects on marine life and water quality.

Innovations in Boom Technology

Recent advancements in spill boom technology have led to the development of more efficient and durable products. These innovations include enhanced absorbent materials that can handle a broader range of chemicals and improved designs that offer better stability in rough waters.

Railroad Track Pans

Railroad track pans are used to collect spills and leaks from railroad cars. They are essential for preventing soil and water contamination in areas where trains frequently load and unload hazardous materials.

The Mechanism of Railroad Track Pans

Railroad track pans function by capturing leaks and spills that occur during the loading and unloading of railcars. They are installed beneath the tracks and are designed to contain and channel hazardous materials into a safe containment system, preventing them from seeping into the ground or waterways.

Benefits of Using Railroad Track Pans

By effectively containing spills, railroad track pans help companies comply with both OSHA and EPA regulations. They reduce the risk of environmental contamination and protect workers from hazardous exposure. Additionally, they can help avoid costly cleanup operations and potential fines associated with environmental violations.

Installation and Maintenance

Proper installation and regular maintenance of railroad track pans are crucial to ensure their effectiveness. This includes routine inspections for damage or wear and timely replacements or repairs as needed to maintain their integrity and functionality.

Oil Absorbent Booms

Oil absorbent booms are specifically designed to absorb oil spills. They are critical tools for industries involved in oil handling and transportation.

Applications of Oil Absorbent Booms

Oil absorbent booms are versatile tools used in various scenarios. In marine spill response, they are deployed in bodies of water to absorb oil spills, minimizing environmental impact. In industrial settings, they help manage oil spills within facilities, ensuring a safer working environment.

Selection Criteria for Oil Absorbent Booms

Choosing the right oil absorbent boom involves considering factors such as the type of oil being handled, the environmental conditions, and the potential size of spills. It’s essential to select booms that are compatible with the specific needs of your operation to ensure maximum effectiveness.

Disposal and Environmental Considerations

Once oil absorbent booms have been used, they must be disposed of properly to avoid secondary contamination. This often involves following specific disposal procedures outlined by regulatory bodies to ensure that the absorbed oil does not pose further environmental risks.

Regulatory Compliance

Compliance with OSHA and EPA regulations involves understanding and implementing the right spill containment practices and equipment.

OSHA Regulations

OSHA regulations require businesses to have a spill response plan, including the use of appropriate equipment like spill containment booms and absorbent materials. Employees should be trained to handle spills safely and efficiently.

Developing a Spill Response Plan

Creating a comprehensive spill response plan involves identifying potential spill scenarios and outlining detailed response procedures. This plan should be regularly reviewed and updated to incorporate new technologies and practices that enhance spill management capabilities.

Training and Certification

Proper training is a cornerstone of OSHA compliance. Employees must be educated on the correct use of spill containment equipment and the procedures for handling various types of spills. Certification programs can further enhance their skills and ensure compliance with regulatory standards.

Monitoring and Reporting

OSHA regulations also require businesses to monitor spill incidents and maintain detailed records. This data is vital for identifying patterns and implementing preventative measures. Regular reporting to regulatory bodies is also necessary to demonstrate compliance and transparency.

EPA Regulations

EPA focuses on preventing environmental contamination. Compliance involves having measures in place to prevent spills from reaching soil and water, using tools like railroad track pans and oil absorbent booms.

Environmental Impact Assessments

Conducting environmental impact assessments helps businesses understand the potential effects of spills on local ecosystems. This information is crucial for developing effective containment strategies that align with EPA guidelines and minimize environmental harm.

Pollution Prevention Strategies

The EPA encourages businesses to adopt pollution prevention strategies that reduce the likelihood of spills occurring in the first place. This can include measures such as regular equipment maintenance, improved storage practices, and the use of environmentally friendly alternatives to hazardous materials.

Enforcement and Penalties

Failure to comply with EPA regulations can result in severe penalties, including substantial fines and legal action. Understanding the enforcement process and the potential consequences of non-compliance underscores the importance of adhering to regulatory requirements.

Implementing a Spill Containment Strategy

Implementing an effective spill containment strategy involves several steps:

Assess Your Needs

Evaluate the types of hazardous materials you handle and the potential spill scenarios. This will guide your choice of spill containment equipment.

Conducting a Risk Assessment

A thorough risk assessment is the first step in developing a spill containment strategy. This involves identifying all hazardous materials on-site, evaluating potential spill scenarios, and assessing the potential impact on workers and the environment.

Identifying Vulnerable Areas

Identifying areas most vulnerable to spills is crucial for prioritizing containment efforts. These areas may include loading docks, storage facilities, and transportation routes. Understanding these vulnerabilities helps in the strategic placement of containment equipment.

Customizing Solutions

Based on the risk assessment, tailor your spill containment strategy to address specific needs. This may involve customizing equipment choices, developing unique response plans, and implementing specialized training programs for employees.

Choose the Right Equipment

Select appropriate spill containment booms, railroad track pans, and oil absorbent booms based on your assessment. Ensure they are compliant with OSHA and EPA standards.

Evaluating Equipment Options

When selecting spill containment equipment, consider factors such as the type of hazardous materials handled, the potential size of spills, and the environmental conditions of your facility. It’s essential to choose equipment that meets both your operational needs and regulatory requirements.

Quality and Reliability

Investing in high-quality equipment ensures reliability and longevity, reducing the risk of equipment failure during a spill incident. Look for products that have been tested and certified to meet industry standards for performance and durability.

Innovations and Technology

Stay informed about the latest innovations and technological advancements in spill containment equipment. New products and technologies can offer improved efficiency, reduced costs, and enhanced compliance with regulatory standards.

Train Your Team

Educate your employees on spill response procedures. Regular training ensures that everyone knows how to use spill containment equipment and respond efficiently in case of a spill.

Comprehensive Training Programs

Develop comprehensive training programs that cover all aspects of spill response, from identifying potential hazards to deploying containment equipment. Include hands-on training sessions to ensure employees are comfortable and confident in their roles.

Ongoing Education and Updates

Regularly update training programs to incorporate new information, techniques, and technologies. Continuous education helps employees stay current with best practices and regulatory changes, enhancing their ability to respond effectively to spills.

Simulation Drills

Conducting simulation drills is an effective way to test your spill response plan and ensure employees are prepared for real-life scenarios. These drills provide valuable insights into the effectiveness of your strategy and highlight areas for improvement.

Regular Maintenance and Inspection

Regularly inspect and maintain your spill containment equipment. This ensures they remain functional and compliant with regulatory requirements.

Routine Inspections

Implement a schedule for routine inspections of all spill containment equipment. Check for signs of wear, damage, or malfunction, and address any issues promptly to maintain the equipment’s integrity and effectiveness.

Maintenance Protocols

Establish clear maintenance protocols that outline the steps for servicing and repairing equipment. Regular maintenance not only ensures compliance with regulations but also extends the lifespan of your equipment, providing long-term cost savings.

Documentation and Record-Keeping

Maintain detailed records of all inspections and maintenance activities. This documentation is essential for demonstrating compliance with regulatory requirements and can be invaluable during audits or investigations.

Benefits of Compliance

Adhering to OSHA and EPA regulations offers several advantages:

Legal Protection

Compliance protects your business from legal issues and potential fines. It demonstrates your commitment to following the law and maintaining high standards of safety and environmental stewardship.

Mitigating Legal Risks

By implementing a comprehensive spill containment strategy, you minimize the risk of legal action and associated costs. Compliance with regulations provides a robust defense against claims of negligence or environmental harm.

Building Trust with Regulators

Demonstrating a proactive approach to compliance helps build trust with regulatory bodies. This can lead to more favorable outcomes during inspections and audits, as well as potential leniency in the event of minor infractions.

Reputation Management

Maintaining compliance enhances your company’s reputation as a responsible and ethical organization. This can lead to increased customer trust, improved employee morale, and a stronger position in the marketplace.

Environmental Safety

Proper spill containment prevents environmental damage, preserving local ecosystems. It underscores your commitment to sustainability and environmental responsibility.

Protecting Natural Resources

Effective spill containment minimizes the impact of hazardous materials on natural resources such as water, soil, and wildlife. This contributes to the preservation of biodiversity and the health of ecosystems.

Contributing to Sustainability Goals

Compliance with environmental regulations aligns with broader sustainability goals, helping your company reduce its ecological footprint. This can enhance your brand image and appeal to environmentally conscious consumers and investors.

Community Relations

By preventing environmental damage, you foster positive relations with local communities. This can lead to increased support for your business operations and a more favorable public perception.

Workplace Safety

Ensuring employee safety through effective spill management reduces the risk of accidents and health hazards. It fosters a safe and productive working environment.

Reducing Workplace Accidents

A well-implemented spill containment strategy reduces the likelihood of workplace accidents, protecting employees from exposure to hazardous materials. This enhances overall workplace safety and reduces the risk of injury-related absences.

Promoting a Safety Culture

By prioritizing spill containment and compliance, you promote a culture of safety within your organization. This encourages employees to prioritize safety in their daily activities and fosters a sense of responsibility and accountability.

Health and Wellbeing

Effective spill management protects the health and wellbeing of your employees by minimizing exposure to harmful substances. This contributes to a healthier workforce and can lead to increased productivity and job satisfaction.

Conclusion

Understanding and implementing OSHA and EPA compliance for spill containment is essential for businesses handling hazardous materials. By using the right equipment and following regulatory guidelines, you can protect your business, employees, and the environment from the risks associated with spills.

Ensuring that your spill containment strategy is comprehensive and up-to-date is not just about compliance; it’s about being a responsible steward of the environment and a proactive protector of workplace safety.

With this complete guide, you’re now equipped to take the necessary steps towards effective spill containment and regulatory compliance. By prioritizing safety and environmental responsibility, you can safeguard your business and contribute to a sustainable future for all.

Shop at Absorbents Online for Spill Containment Solutions

Take the next step in ensuring your business’s safety and compliance by shopping at Absorbents Online. Explore our wide range of high-quality spill containment equipment designed to meet OSHA and EPA regulations. With innovative products that enhance efficiency and reduce costs, you can protect your employees and the environment effectively. Don’t wait—visit us today and invest in the best spill containment solutions for your organization!