In today’s environmentally-conscious world, effective spill control is more critical than ever. Whether you’re dealing with oil spills on the water or chemical leaks on land, using the right combination of tools can make all the difference. Containment booms and absorbent products are two essential elements in managing spills effectively. Let’s explore how these tools work and how they can be paired together for maximum spill control.

Understanding Containment Booms

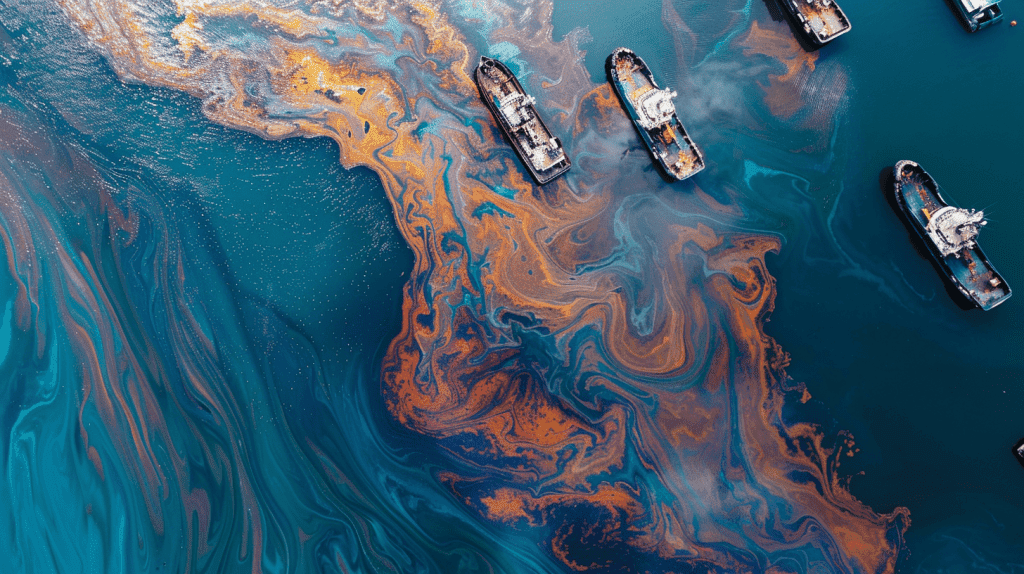

Containment booms are floating barriers used to contain and control the spread of oil spills on water. These barriers are crucial for preventing oil slicks from reaching shorelines and sensitive ecosystems. Typically, containment booms are made from durable materials that can withstand harsh environmental conditions, including UV rays and corrosive substances.

Types of Containment Booms

There are several types of containment booms, each designed for specific conditions and spill scenarios:

- Inshore Booms: Ideal for calm waters, such as harbors and marinas.

- Offshore Booms: Built to handle rougher waters and more significant spill events.

- River Booms: Designed for use in flowing waters, these booms are flexible and can adapt to changing water levels.

Understanding the different types of booms will help you select the right one for your specific spill situation.

Absorbent Products: The Basics

Absorbent products are designed to soak up spills, preventing them from spreading and causing further damage. These products come in various forms, including pads, rolls, socks, and pillows. They are typically made from materials that can absorb oil, water, or chemical spills.

Types of Absorbent Products

Absorbent products are categorized based on their absorbency capabilities:

- Oil-only Absorbents: These are hydrophobic, meaning they repel water while absorbing oil. They are ideal for oil spills on water.

- Universal Absorbents: Capable of absorbing both oil and water-based liquids, making them versatile for various spill scenarios.

- Hazmat Absorbents: Specifically designed for hazardous chemical spills, these absorbents are essential in industrial settings where chemicals are prevalent.

By understanding the types of absorbents available, you can choose the most effective product for your spill control needs.

Pairing Containment Booms with Absorbent Products

The synergy between containment booms and absorbent products is crucial for comprehensive spill control. Here’s how to effectively pair these tools to maximize efficiency:

Step 1: Deploy Containment Booms

First, deploy containment booms around the spill area. This step is essential to prevent the spread of the spill and to contain it within a designated area. Ensure that the booms are securely anchored and that they form a continuous barrier around the spill.

Step 2: Apply Absorbent Products

Once the spill is contained, apply the appropriate absorbent products within the boomed area. For oil spills on water, oil-only absorbents should be used to soak up the oil without absorbing water. For chemical spills, hazmat absorbents are necessary to safely manage the spill.

Step 3: Monitor and Adjust

Spill control is an ongoing process. Continuously monitor the spill area to ensure that the booms and absorbents are functioning effectively. Adjust the booms as needed to accommodate changing conditions, such as tides or currents, and replace saturated absorbents promptly.

Best Practices for Spill Control

To achieve maximum spill control, follow these best practices:

- Regular Training: Ensure that personnel are well-trained in spill response procedures and the proper use of containment booms and absorbent products.

- Maintenance and Inspection: Regularly inspect and maintain spill control equipment to ensure it’s in good working condition.

- Develop a Spill Response Plan: Having a clear and concise spill response plan in place can significantly reduce response time and improve the effectiveness of your spill control efforts.

Conclusion

Effectively managing spills requires the right combination of tools and techniques. By understanding the functions of containment booms and absorbent products, and how to pair them effectively, you can enhance your spill control capabilities. Whether dealing with oil spills on water or chemical spills on land, the synergy between these tools can help protect the environment and minimize damage. Always stay prepared, practice regularly, and maintain your equipment to ensure the best possible outcome in spill response efforts.

Shop at Absorbents Online for Spill Containment Solutions

Ready to enhance your spill control efforts? Visit Absorbents Online today to explore a wide range of containment booms and absorbent products tailored for every spill scenario. Equip yourself with the best tools to protect the environment and ensure effective spill management. Don’t wait—shop now and be prepared for any spill situation!