Tips on Fuel Leak Containment Systems and Spill Prevention

Where there’s fuel, there’s a danger of leaks. Is your company ready to deal with spills?

Does your company have a fuel containment plan in the event of a spill? Whether it’s petrol-based gasoline, diesel or kerosene, fuel is a highly flammable liquid that can lead to fires and explosions. And since most industrial businesses use fuel to power machines and vehicles, spills are an all-too-common occurrence.

Allowing fuel to spread unchecked poses many undesirable outcomes. Firstly, it places nearby employees at risk for injury. This violates Occupational Safety and Health Administration (OSHA) regulations. Large fuel leaks can also create environmental pollution, leading to expensive clean-up activities. Worse, breaching Environmental Protection Agency (EPA) rules can lead to hefty fines.

These are all very important reasons is why it’s imperative for companies to have a fuel spill containment plan in place. In fact, having such a plan is a requirement for EPA Spill Prevention, Control and Countermeasure (SPCC).

So, be smart and be SPCC ready! In this article you will learn more about preparing for spill response to fuel leaks.

How does your site store and use fuel?

From construction to farming, if your industry requires fueling equipment then you’ll likely have a fuel storage tank on site. Also likely is that you’re transporting this hazardous liquid around. For example, to refuel tractors, trucks and other machinery. Your fuel spill containment plan needs to cover both of these situations.

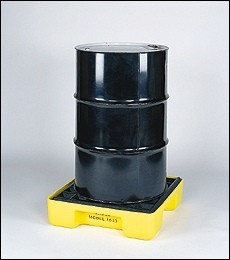

All fuel storage containers must have secondary containment and overfill protections in place. This includes your fuel tanks, intermediate bulk containers (IBC), totes, and drums. Spill containment pallets, spill decks, and spill containment berms are popular options for these large containers.

Likewise, you must have spill control systems when using mobile fuel refilling equipment. Drip pans or portable containment trays are practical solutions to capture fuel overflows. And let’s not forget about using gas cans with the Department of Transportation (DOT) stamp of approval. As well, be sure to house your fuel and combustible cans in a secure, leak-proof chemical storage safety cabinet.

Are there drains nearby that fuel can spill into?

When you’re creating a fuel spill containment plan for your company, check to see if there are any stormwater drains nearby. If fuel were to spill and travel down a storm drain, it could end up polluting nearby ponds, rivers, lakes and water reservoirs. As well as damaging the eco-system, this leaves your company vulnerable to fines and sanctions handed down by the EPA.

Covering a drain is a quick and easy process that takes less than a minute. You can read more about drain covers in our previous blog post. But, the idea is to cover drains with a mat made of professional-grade polyurethane. Once the mat lays over the drain, it creates a waterproof barrier which prevents any liquid, including fuel, from passing through. It’s not a bad idea to keep drain cover mats around each of the stormwater drains in your workplace.

Using secondary containment systems and fuel spill products

From heavy duty fuel tank containment tubs to portable spill dikes, there’s a huge variety of containment products out there.

Next, we’ll break down a few of the different options available on the market.

Containing fuel leaks with spill berms, dikes and booms

The first step to preventing a spill or fuel cleanup event is containment. The farther a spill spreads, the more damage it will do. So, how do you contain a spill? One solution to leaks on land, is a spill containment berm or dike. The equivalent product in marine environments is a spill boom.

Basically, these devices create an impenetrable perimeter around a fuel container or storage tank. That is, the wrapping forms a containment area so that potential spills remain inside.

Fuel, like oil, floats to the top of water, which is why some of these containment units don’t have a bottom. As fuel floats on the surface, it becomes trapped by the containment unit sides or walls which makes the spill easier to control and clean up.

Spill containment units come in a wide variety of styles and size options. Some require assembly, and use brackets to hold up the containment walls. Other spill containment berms are portable, or, have flexible walls that automatically rise in the event of a fuel leak.

With so many choices, you’re sure to find a solution for your facility – no matter what type of fuel container you have, or where you store it.

Fuel spill cleanup solutions

With fuel safely contained inside a spill berm, your next step in a fuel spill containment plan is to then remove or recover it. There are several different ways to approach this scenario. Depending on the type of container, you may be able to install and use a drainage sump. Or, absorbent pads, pillows, booms and spill kits can help soak up the fuel.

Choose the method that’s best suited towards your particular needs. And when in doubt, stick with a universal spill kit that can handle both fuel and water-based liquids.

Spill prevention and planning overview

Remember, the best way to deal with a spill is to stop it before it even happens. That’s why critical planning is so important. Here’s a high level outline of some key steps to prepare and maintain your spill containment plan.

Review and assess your facility at least once a year

Identify possible spill locations and types that exist at your location. This could include any new equipment or fuel storage areas you may have set up. Inspect all fuel storage containers to identify potential pinhole leaks before a major rupture occurs. Take stock of existing containment products and spill kits. Ensure contents are complete and in good working condition.

Put spill and leak countermeasures in place

Prepare for the unexpected with an emergency leak repair kit for any container damage. Use absorbents and secondary containment systems we outline above for spill response at your facility. Keep a list of local agency contacts, like the fire department, if it is necessary to communicate a spill incident.

Conduct frequent training

Now your site has all the necessary equipment in place, does your staff know how to access and use it? Time is of the essence when it comes to spills. So, it’s essential that your team is familiar with relevant products and process.

Take note of any applicable SPCC regulation updates

As we mention before, Federal and local State guidelines mandate many rules and requirements when it comes to fuel and oil spills. Ensure your business stays up to date on any changes or updates that may affect your facility.

Update your containment and prevention plan

With the above steps complete, be sure to document any changes and update your plan as necessary. Think of your plan as containing dynamic content that will evolve and change over time.

The bottom line? Planning is key when it comes to spill control and spill response. Make sure your company is capable of containing and cleaning up fuel—or any hazardous material—should a workplace spill occur.

AbsorbentsOnline.com – Your Secondary Containment and Absorbent Experts

Questions about spill containment or cleanup equipment for your company? Talk to us! Proudly delivering our United States customers with excellent service and products since 1985.

This is a revision to a blog post with an original publish date of October 29, 2013