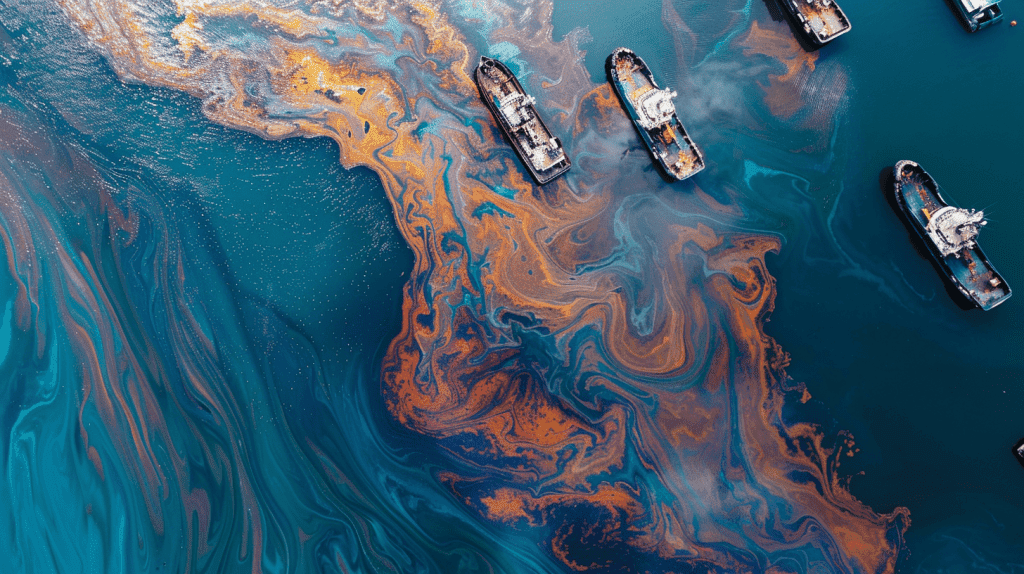

Selecting the right spill containment boom is crucial for effectively managing and containing spills in various industries. Whether you’re dealing with oil spills on water, hazardous material spills on land, or routine bilge water management, choosing the right boom can make all the difference. This article will guide you through the process of selecting the best spill containment boom for your specific needs.

Understanding Spill Containment Booms

Spill containment booms are barriers used to contain and control the spread of spills. They are commonly used in marine environments to manage oil spills but are also applicable on land for containing hazardous materials. Booms come in various shapes, sizes, and materials, making it essential to choose the right one for your specific industry and spill scenario.

Types of Spill Containment Booms

There are several types of spill containment booms, each designed for different applications:

- Oil Spill Booms: These are used in marine environments to contain oil spills on water.

- Bilge Booms: These are designed to absorb oil and other hydrocarbons from bilge water in boats.

- Land-Based Booms: These are used to contain hazardous material spills on land, such as chemicals or fuel.

Factors to Consider When Selecting a Spill Containment Boom

1. Type of Spill

The first factor to consider is the type of spill you need to contain. Oil spills, chemical spills, and bilge water management all require different types of booms. Understanding the nature of the spill will help you choose the most effective containment solution.

2. Environment

Consider the environment where the boom will be deployed. Marine environments, freshwater bodies, and land-based spill sites all have different requirements. For example, oil spill booms used in open water need to be more robust and weather-resistant compared to those used in calm, sheltered waters.

3. Material

The material of the boom is crucial for its effectiveness. Common materials include:

- PVC: Durable and resistant to chemicals, ideal for oil and chemical spills.

- Polyurethane: Flexible and resistant to oil and UV rays, suitable for various environments.

- Absorbent Materials: Used in bilge booms to absorb hydrocarbons from water.

4. Size and Length

The size and length of the boom are important for adequate coverage. Larger spills require longer and more robust booms, while smaller spills can be managed with shorter booms. Measure the area you need to contain to determine the appropriate size.

5. Deployment and Retrieval

Consider how easy it is to deploy and retrieve the boom. Some booms are designed for quick deployment and can be easily stored and transported, while others may require more effort and equipment. Choose a boom that matches your operational capabilities.

Oil Spill Booms

Oil spill booms are specifically designed for marine environments. They are used to contain and control the spread of oil on water, preventing further contamination and facilitating cleanup efforts.

Key Features of Oil Spill Booms

- High Buoyancy: Ensures the boom stays afloat even in rough waters.

- Durable Material: Resistant to oil, UV rays, and harsh weather conditions.

- Easy Deployment: Designed for quick and efficient deployment in emergency situations.

Applications

- Marine Oil Spills: Containing oil spills in oceans, seas, and other large water bodies.

- Ports and Harbors: Preventing oil spills from spreading in ports and harbors.

- Lakes and Rivers: Containing oil spills in freshwater environments.

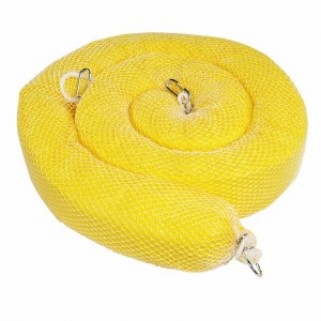

Bilge Booms

Bilge booms are used to manage bilge water in boats. They are designed to absorb oil and other hydrocarbons from the water, preventing pollution and maintaining a clean bilge.

Key Features of Bilge Booms

- Absorbent Materials: Specifically designed to absorb hydrocarbons while repelling water.

- Compact Size: Fits easily in bilge compartments.

- Easy Disposal: Can be easily removed and disposed of once saturated.

Applications

- Boat Bilge Management: Keeping bilge water clean and free from oil and other contaminants.

- Marinas and Docks: Preventing oil pollution in marina and dock areas.

Land-Based Spill Containment Booms

Land-based spill containment booms are used to contain hazardous material spills on land. They are essential for managing chemical spills, fuel leaks, and other hazardous substances.

Key Features of Land-Based Booms

- Chemical Resistance: Made from materials that resist various chemicals and hazardous substances.

- Flexible Design: Can be shaped and positioned to contain spills on uneven surfaces.

- Durable Construction: Built to withstand harsh environmental conditions.

Applications

- Industrial Sites: Containing chemical spills in manufacturing and industrial environments.

- Fuel Stations: Managing fuel leaks and spills at gas stations.

- Construction Sites: Containing hazardous material spills during construction activities.

Conclusion

Selecting the right spill containment boom is essential for effectively managing spills in your industry. By considering factors such as the type of spill, environment, material, size, and ease of deployment, you can choose the best boom for your specific needs. Whether you need to contain oil spills on water, manage bilge water in boats, or control hazardous material spills on land, the right spill containment boom will help you protect the environment and maintain safety.

Investing in the appropriate spill containment boom not only ensures compliance with environmental regulations but also demonstrates your commitment to environmental stewardship. Make an informed choice and equip your industry with the best spill containment solution available.

Shop for Absorbent Booms at Absorbents Online

Take the next step in ensuring environmental protection and compliance by choosing the highest quality absorbent booms available. At Absorbents Online, we offer a wide range of products designed to tackle various spill scenarios with ease and efficiency. Whether you’re dealing with oil spills on water, bilge water management, or hazardous material containment, our selection of absorbent booms will provide you with the reliability and performance you need. Visit our website today to explore our full catalog and invest in the best spill containment solution for your industry. Let us help you safeguard the environment while maintaining the highest safety standards.