Tips for choosing hazardous material safety cabinet storage solutions

Heavy duty safety storage cabinets are the first line of defense against fires, spills and contamination. As their name suggests, these cabinets ‘safely’ store hazardous chemicals, corrosives and flammables. In fact, there are many regulations around safe storage. One important governing body is Occupational Safety and Health Administration (OSHA). Another is the National Fire Protection Association (NFPA).

Storage cabinets offer a safe, EPA-friendly method for storing potentially hazardous chemicals. This includes pesticides, flammables, corrosives and combustibles. Rather than leaving these items out in the open—susceptible to accidents—keep them in a cabinet.

Unlike basic models, professional-grade storage units can withstand pressure, heat and force. This ensures that they can protect the chemical contents you plan to store inside them.

But with so many different flammable storage cabinets on the market, how do you know which one to choose? Here we outline several important factors to consider before making your cabinet investment. Use this as a guide to help select the cabinet that’s best for your needs.

Identify your storage needs

So what’s the first step in choosing the right cabinet for your company? Identify its current and future storage needs. Perform an inventory of all on-site chemicals, including their volume or quantities. And make sure you cover all material types. For instance, everything from liquid gasoline fuels, to aerosol can paints, or corrosive acids. This helps determine exactly what types of cabinet best suit your particular requirements.

Always separate stored materials, like flammable liquids, by their hazmat classifications

Safety storage cabinets break down into different categories based on what they are capable of storing. Above all, ensure you segregate materials by their hazmat classification. And only contain contents in cabinets of an appropriate material construction. Bear in mind OSHA only allows you to store certain volumes of materials in a single cabinet.

A cabinet’s color and exterior warning label identify the hazardous material inside. The cabinet shell and internal shelves must allow spill containment of liquid leaks. For safety purposes, all cabinets should be lockable. Some cabinets enable you to add a padlock for extra security.

Selecting the right cabinets for the specific material handling elements in your workplace is crucial. Next we’ll outline the different types of cabinets available, and their purposes, to help you decide which one is right for you.

Safety cabinet types and options

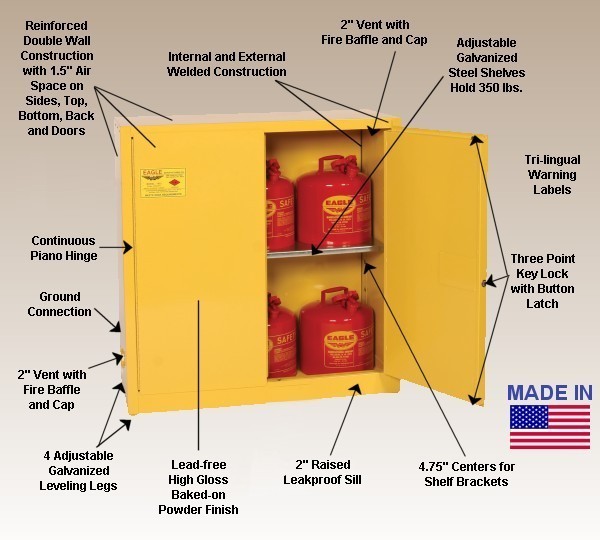

Flammable liquid storage

Flammable liquid storage cabinets require 18-gauge steel construction for optimal fire resistance. They are usually are yellow in color. Various flammable cabinet size and configuration options are available, from 4 to 90 gallon capacity. Choose between manual door or self-close doors. Flammable liquid safety cabinets must protect contents for a period of 10 minutes to follow OSHA and NFPA Code 30 requirements.

Paint and ink storage

Ink and paint safety cabinets are the ideal solution to house your combustible liquid and aerosol cans. Colors include either red or yellow powder-coat steel. They are available in many sizes and configurations, with or without self-closing doors. Adjustable height shelves help maximize space and organize ink or paint cans. In locations with moisture concerns, select a tower cabinet with legs for better ventilation.

Acids and corrosives storage

Different color cabinets help easily identify storage contents

Corrosive and acid safety cabinets offer superior resistance to chemical vapors and spills. Made of durable steel or polyethylene, these chemical storage cabinets are usually blue. They come in many sizes, including options that fit below countertops, bench tops and lab workbenches. Select cabinets with poly construction for aggressive sulfuric, nitric or hydrochloric acids. Never store nitric and sulfuric acids in the same cabinet unit.

Pesticide storage

Pesticide safety storage cabinets hold toxic pesticide and insecticide chemicals. They are typically green and made of heavy-duty steel with either self or manual close doors. Corrosion-resistant polyethylene shelves help keep chemical storage cabinets in good condition. This style safety cabinet is a great option for agricultural companies storing chemical poisons.

Drum storage

Drum storage cabinets are suitable for various 30 or 50 gallon combustible or hazardous materials. The default color is yellow, for flammable hazard classification.

Choose between horizontal or vertical storage units, with or without self-closing doors.

Hazmat drum cabinet models feature roller conveyors in the bottom for easy material handling.

What storage cabinet material should you choose?

The materials used in the construction of storage cabinets can vary depending on their intended chemical. However, stainless steel and polyethylene are the most common materials for professional-grade cabinets. Both of these materials offer a superior level of strength, durable and longevity. These properties are essential when it comes to storing potentially hazardous chemicals.

Steel cabinets are not suitable to store sulfuric, hydrochloric and nitric acids. In other words, choose a polyethylene cabinet instead noting that this material isn’t non-flammable. Poly acid cabinets also feature a sealed internal containment sump, plus vents.

You’ll find that some safety storage cabinets for sale feature a corrosion-resistant powder coating. This layer serves as another barrier of protection. If a corrosive chemical tips over, the powder coating helps protect the cabinet from damage. Powder coating is a standard feature of all steel safety cabinets available at AbsorbentsOnline.com.

Check out these guides for more details about:

What space accommodations does your site need?

Of course, you’ll also want to pay close attention to the size of a safety storage cabinet. Different capacity and configuration styles will help you maximize available floor space. Identify the storage needs of your company and then choose the right size to match.

Besides regular floor type models, cabinets come in several other styles. These include slimline, tower, stackable, under-counter or wall mount designs. Most feature adjustable shelves to accommodate custom storage containment.

Tower cabinet models, with adjustable legs, are a good option for sites with un-level floors or moisture issues. The 4in clearance increases ventilation and reduces potential corrosion. Feet will also allow you to place a cabinet over vents or wires. This cabinet style proves easy to move around your facility with a forklift or pallet jack. Likewise, units with roller inserts help quick access to 55-gallon drums.

Verify cabinet compliance and approval ratings

Check for safety storage cabinet compliance and approval ratings

It pays to find out if your state/county require premises to meet specific regulations for flammable liquid storage. For example, self-closing doors are mandatory in some states following the International Fire Code (IFC). Other local authorities have jurisdiction over cabinet placement. Or, how many flammable storage cabinets they will allow in one location.

Independent third-party certifications provide confidence a cabinet passes rigorous testing for safe storage. Factory Mutual Global (FM) or Underwriters Laboratory (UL) are two such certifications. OSHA and NFPA approval are also essential requirements when choosing a cabinet.

Review our summary and guide to OSHA cabinet storage regulations here.

Need help finding affordable safety cabinets?

Have questions or need advice about selecting the right cabinet? Contact us!

Talk to AbsorbentsOnline.com today about safety storage cabinet solutions for your work area.

We can help with everything from combustible liquid safety cans to spill containment products.

Stockists of leading brands like Eagle and Justrite, we are proud to have been offering excellent customer service since 1985.

This is a revision to a post with an original publish date of September 24, 2013

Do you have the right safety products on hand for your workplace? To find out, contact Angie Meza at

Do you have the right safety products on hand for your workplace? To find out, contact Angie Meza at

With their spill response plans in place, here are three main types of

With their spill response plans in place, here are three main types of

Ergonomically designed AbsorbentsOnline

Ergonomically designed AbsorbentsOnline

Whether it’s as simple as a

Whether it’s as simple as a

The only thing more important than your equipment safety is the safety of your employees. Which is why you need the right industrial safety products on hand. In short, to keep both your equipment and employees safe under all possible circumstances. And help ensure you comply with

The only thing more important than your equipment safety is the safety of your employees. Which is why you need the right industrial safety products on hand. In short, to keep both your equipment and employees safe under all possible circumstances. And help ensure you comply with  Many facilities paint their columns the same color as the walls. Which makes columns difficult to see. Particularly when operating vehicles like forklifts, tow motor lifts, or carts. A collision with a column can cause damage to your facility and your equipment — not to mention your employees!

Many facilities paint their columns the same color as the walls. Which makes columns difficult to see. Particularly when operating vehicles like forklifts, tow motor lifts, or carts. A collision with a column can cause damage to your facility and your equipment — not to mention your employees! Similarly, you can protect high-traffic areas in your facility with

Similarly, you can protect high-traffic areas in your facility with  Repairing damage to drywall, concrete, or block walls can be expensive. But you can prevent this damage with

Repairing damage to drywall, concrete, or block walls can be expensive. But you can prevent this damage with  Don’t let fluids from your forklifts damage your floors or present employee slip hazards.

Don’t let fluids from your forklifts damage your floors or present employee slip hazards.  It’s especially important to protect your floors in high-traffic areas. That’s because this is where small spills and leaks tend to frequently happen.

It’s especially important to protect your floors in high-traffic areas. That’s because this is where small spills and leaks tend to frequently happen.  When absorbent mats just don’t cut it, try

When absorbent mats just don’t cut it, try