When it comes to workplace safety, spill preparedness is a critical part of maintaining a clean, compliant, and hazard-free environment. But not all spills are created equal, and neither are the work zones where they happen. This is why customizing spill kits based on the specific needs of your work zone is essential for effective spill containment and cleanup.

At Absorbents Online, we understand the unique demands of different industries and environments. Whether you operate a manufacturing plant, a laboratory, an office, or a construction site, your spill kits should be as tailored as your operations. In this blog, we’ll explore why customizing spill kits matters, how different work zones influence spill kit design, and how you can create the perfect kit for your needs.

Why Customize Spill Kits?

Standard spill kits often include a generic assortment of absorbents and safety tools designed to handle a wide range of liquid spills. While these are useful for general purposes, they may not address the specific types of spills or hazards present in your unique work environment. Using a generic kit could mean unnecessary materials, wasted money, or worse, ineffective spill control that compromises safety and compliance.

Customizing spill kits ensures that you have the right absorbents and safety equipment on hand exactly when and where you need them. This means faster cleanup times, minimized environmental impact, and reduced risks to your employees.

Factors Influencing Spill Kit Customization by Work Zone

1. Type of Spill Material

Different work zones handle different liquids, from oils and fuels to harsh chemicals or even water-based fluids. Selecting the correct absorbent is critical:

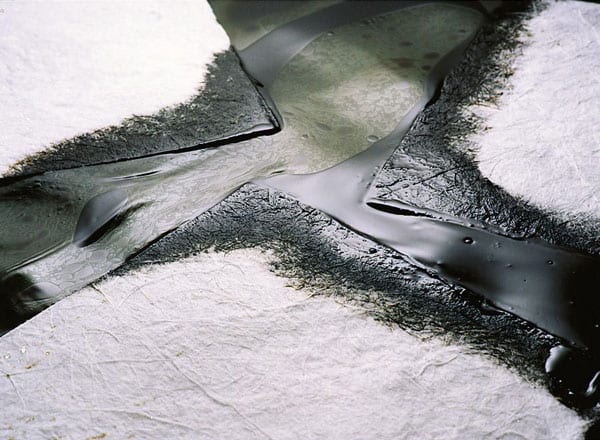

- Oil-Only Absorbents: Ideal for automotive shops or fuel stations; these absorbents repel water but soak up hydrocarbons.

- Universal Absorbents: Suitable for general purpose spills involving water-based and oil-based liquids.

- Chemical Absorbents: Necessary in labs or chemical plants, these absorbents are designed to handle hazardous liquids safely.

2. Spill Volume and Frequency

A manufacturing plant with heavy machinery might face larger, more frequent spills, requiring spill kits with higher capacity absorbents like larger pads and socks. Conversely, an office environment may only need a small spill kit for occasional leaks or minor accidents.

3. Environmental Conditions

Outdoor worksites need spill kits that can withstand weather elements and provide effective containment on uneven surfaces. Indoor zones might prioritize compact kits that fit within tight storage spaces or meet specific regulatory requirements.

4. Regulatory Compliance

Certain industries are subject to strict OSHA, EPA, or local environmental regulations dictating spill response protocols. Customizing your spill kit helps ensure compliance by including the proper PPE, disposal bags, and absorbents specified for your zone.

5. Employee Safety

Including the right safety gear like gloves, goggles, and disposal bags helps protect workers during spill cleanup. This is particularly important in hazardous chemical zones or heavy industrial settings.

Custom Spill Kit Components for Common Work Zones

Industrial and Manufacturing

- Absorbents: Heavy-duty universal or chemical absorbents, large socks and pillows.

- Safety Gear: Chemical-resistant gloves, goggles, disposal bags.

- Extras: Drain covers, patch kits for quick fixes, durable containers.

Laboratories and Chemical Plants

- Absorbents: Specialized chemical absorbents rated for acids, solvents, and hazardous materials.

- Safety Gear: PPE suited for chemical exposure (respirators, splash goggles).

- Extras: Spill neutralizers, detailed cleanup instructions.

Automotive and Fuel Stations

- Absorbents: Oil-only pads and socks to soak up fuels and oils.

- Safety Gear: Gloves resistant to petroleum products, disposal bags.

- Extras: Fire-resistant spill containers.

Offices and Commercial Spaces

- Absorbents: Universal absorbent pads for small liquid spills like coffee or water.

- Safety Gear: Basic gloves and disposal bags.

- Extras: Compact kits for easy storage under desks or in janitorial closets.

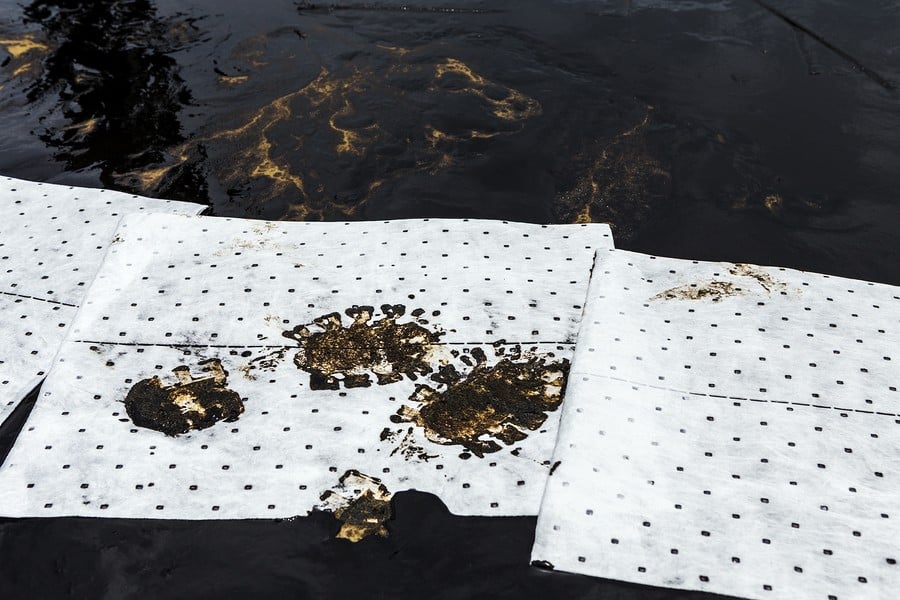

Outdoor and Construction Sites

- Absorbents: Heavy-duty, weather-resistant absorbents that can handle oil, water, and chemicals.

- Safety Gear: High-visibility gloves, goggles, and large disposal bags.

- Extras: Portable containment berms or barriers.

How to Build Your Custom Spill Kit with Absorbents Online

Creating a custom spill kit might sound complicated, but it’s easier than you think with the right guidance:

- Assess Your Work Zone: Identify the types of liquids you deal with, typical spill sizes, and frequency.

- Choose the Absorbents: Pick absorbents specific to your spill types (oil-only, universal, or chemical).

- Select Safety Gear: Ensure your kit has gloves, goggles, and disposal bags matching your spill hazards.

- Add Extras: Depending on your needs, add items like drain covers, neutralizers, or spill pillows.

- Optimize Kit Size and Storage: Make sure your kit is large enough for your expected spills but fits conveniently in your workspace.

Why Shop Spill Containment Solutions at Absorbents Online?

At Absorbents Online, we specialize in spill containment solutions designed to meet the needs of diverse industries. Our extensive product selection lets you customize spill kits tailored precisely to your work zone challenges. With expert guidance, fast shipping, and competitive pricing, we make it simple to stay compliant, safe, and prepared.

Conclusion

No two work zones are alike, and your spill kit shouldn’t be either. Customizing your spill containment solutions to your specific environment is the smartest way to manage risks, protect employees, and maintain regulatory compliance. From heavy industrial sites to office spaces, tailored spill kits from Absorbents Online ensure you have the right tools ready for any spill emergency.Ready to build your perfect spill kit? Shop now at Absorbents Online and discover our wide range of customizable spill containment solutions designed for your unique work zones.