When faced with the daunting challenge of an oil spill, selecting the right absorbent boom can be the key to swift and efficient spill containment.

Not all booms are created equal; the variance in absorbency rates, durability, and compatibility with different hydrocarbons calls for a well-informed decision.

From understanding the specifics of the spill to ensuring compliance with environmental regulations, identifying the most suitable absorbent boom is a complex but essential part of effective spill management.

Each material, whether it be synthetic fiber or natural fiber like cotton or wool, plays a critical role in the boom’s performance.

In this article, we’ll guide you through the nuances of various absorbent booms to help you make an informed choice, ensuring you’re prepared for any spill scenario.

Understanding Your Spill: Sizing Up the Situation

Confronting an oil spill, I understand that selecting the right absorbent material is pivotal.

My initial step in responding to an incident involves a meticulous evaluation of the type of oil discharged.

Is it a thicker crude or a lighter fuel?

Recognising the consistency and makeup of the oil is vital since different absorbents have affinities for varying hydrocarbon types.

The spill’s volume also demands my attention – too little absorbent and I’m running an ineffective cleanup; too much and I waste valuable resources.

Moreover, I am acutely aware of the surrounding environment where the spill has occurred.

Whether it’s on water, involving containment booms and pillows, or land, necessitating absorbent pads and granular sorbents, the context dictates my approach to ensure that I employ a robust yet environmentally friendly cleanup operation.

Evaluate the Type of Oil Spilled

When faced with a spill, my initial task is to scrutinise the characteristics of the oil involved. This involves discerning whether the oil is a volatile substance like gasoline, which evaporates quickly and poses a significant risk of ignition, or a more viscous type like crude oil, which may persist in the environment for longer durations.

My experience has taught me that understanding the specific nature of the oil can dramatically alter the selection of absorbent material required. Taking into account factors such as the oil’s viscosity and its tendency to emulsify in water enables me to make an informed decision when choosing between absorbent options like booms, mats, or granular agents.

Assess the Spill Volume

Quantifying the volume of the spill is a process I execute with precision, as it profoundly influences the quantity of absorbent material I require. A spill’s extent, from a minor puddle to an expansive slick, necessitates different strategies and tools, whether it’s absorbent pads for smaller leaks or oil absorbent booms to corral larger volumes at sea.

Through careful consideration, I calculate the spread rate of the fluid, incorporating factors like oil type and environmental conditions, which helps me determine the amount of absorbent boom needed. It’s about finding that balance – ensuring enough material to contain and absorb the spill effectively without any excess that might later contribute to waste disposal challenges.

Consider the Environment Around the Spill Area

Assessing the environmental context of the spill area is a step I approach with the utmost respect for the ecological balance. If a spill occurs near sensitive habitats or shorelines, I select an absorbent boom designed for gentle and precise application, to minimise disturbances and prevent further intrusion of pollutants.

In urban or industrial settings, where spills might interface with complex infrastructures or traffic, I lean towards robust and durable oil absorbent materials. These need to withstand not just the spill, but also the movements of forklifts, pallet handling, and other dynamic activities that define such environments.

Different Types of Oil Spill Absorbent Booms

Choosing the correct oil spill absorbent boom requires distinct consideration for the spill’s location and nature.

I’ve learned that when dealing with marine environments, floating booms are indispensable, crafted to contain and absorb hydrocarbons while repelling water.

For coastal areas, where oil could detrimentally impact delicate ecosystems, shoreline booms present a targeted solution, designed to intercept oil as it washes ashore.

And when a spill is modest in scale, maybe just a slip-up in a maintenance facility, I reach for specialized absorbent booms, small yet effective in their capacity to soak up the spill.

Each type addresses specific demands of the spill scenario, ensuring both efficacy and environmental safety in their application.

Floating Booms for Marine Environments

Working with floating booms in marine environments, I’ve embraced their distinct capability to mitigate the spread of oil on the surface of the water. These booms float on the water while their skirts hang down to trap oil and prevent it from spreading, a method proving indispensable for prompt oil spill response in open water.

I’ve witnessed the resilience of floating booms first-hand; they’re designed to endure the harsh marine conditions, offering prolonged containment and absorption of hydrocarbons. Selecting a boom with a robust outer netting and strong connectors ensures it can withstand the force of waves and tides, which is a critical factor in my decision-making for marine applications.

Shoreline Booms for Coastal Areas

Deploying shoreline booms for coastal areas requires a sensitive approach, especially given the proximity to wildlife and ecosystems that can be easily disrupted. In these regions, I meticulously select booms that are not only effective at containing oil but also ensure minimal interference with natural habitats.

In my work along coasts, I opt for shoreline booms that are sturdy enough to combat the varying tides and potential debris, yet possess a design that aligns with the shore’s natural contour. This nuanced alignment is critical to maintaining the integrity of the containment line, maximising the protection against incoming oil.

Absorbent Booms for Small Scale Spills

For those unexpected mishaps in workshops or on factory floors, small scale absorbent booms provide a targeted response, swiftly encapsulating the spill to prevent it from spreading. Their compact design suits narrow spaces, enabling me to navigate around machinery and swiftly address the contamination without impeding workplace activity.

I have found that these diminutive yet effective barriers are excellent for quick deployment, acting as both a deterrent to slippery surfaces and a means of proactive maintenance. They are particularly efficient at soaking up leaks and drips from equipment, providing a simple solution that upholds safety and cleanliness within the working environment.

Factors to Consider When Choosing an Absorbent Boom

Deciding on the most suitable absorbent boom for your oil spill situation is a complex process, one which requires consideration of several critical factors.

The absorbency rate and capacity of the boom determine how effectively it can tackle the spill at hand, pulling in the unwanted fluids without reaching saturation too quickly.

Equally important is the adaptability of the boom to various environments; whether the spill occurs in a bustling harbour or a tranquil pond, the chosen boom needs to cope with the unique challenges posed by each setting.

Additionally, the durability and ease of deployment greatly influence the efficiency of spill management because I seek a quick and steadfast response to limit environmental damage and health risks.

These primary factors guide me in selecting an absorbent boom that not only meets the needs of the present spill but also stands as a reliable resource for any future incidents.

Absorbency Rate and Capacity

My decision-making process always involves a critical look at the absorbency rate and capacity of any boom I consider. The key is to match the material’s properties with the expected rate of absorption, ensuring that the boom effectively contains and soaks up oil without reaching saturation point prematurely, which could cause a secondary spill and complicate cleanup efforts.

In my practise, I constantly monitor the performance of the booms in action, understanding that their capacity to secure and absorb oil shouldn’t be compromised over time. I seek out booms that maintain their integrity throughout the cleanup process, absorbing consistently and reliably to prevent any leakage or escape of pollutants back into the environment.

Adaptability to Different Environments

In my line of work, versatility is crucial, and evaluating the adaptability of an absorbent boom to different environments is no exception. When selecting a boom, I need to be confident in its ability to perform not only along coastlines and marine settings but also in the confinement of ditches and on concrete floors where spills can also pose significant risks.

The dynamics of each spill area, influenced by factors such as weather, temperature, and wave action, can affect the efficacy of the chosen absorbent. Thus, I make it a priority to opt for a solution that is not only robust but flexible, one that seamlessly conforms to varying topographies and conditions, ensuring complete and effective spill containment.

Durability and Ease of Deployment

My approach to selecting an absorbent boom invariably includes an assessment of its durability. This means I look for materials robust enough to endure the challenging conditions of a spill environment, from resisting the corrosive nature of certain hydrocarbons to weathering the beating of waves and ultraviolet rays over extended periods of time.

Additionally, the ease of deploying an absorbent boom plays a central role in its overall effectiveness in managing an oil spill. I favour booms that are straightforward to unroll and install, so rapid response teams can act quickly, minimising environmental impact and potential health hazards without complicated setup procedures.

The Role of Material in Absorbent Booms’ Effectiveness

As I delve further into the intricacies of oil spill containment, I recognise that the efficacy of an absorbent boom largely hinges on the materials used in its construction.

It’s a matter of choosing between synthetic fibers, known for their durability and high absorbent capacity, and natural fibers, which are appreciated for their environmentally friendly attributes and innate biodegradability.

The material not only determines how well the boom performs in terms of absorption but also its environmental footprint post-use—critical factors in areas where ecological sensitivity and sustainability are paramount considerations.

Synthetic vs. Natural Fibres

In my professional judgment, the selection between synthetic and natural fibres boils down to their application and impact. Synthetic fibres, such as polypropylene, are prized for their oil affinity and resilience, making them benchmarks for industrial spill scenarios where performance and durability are non-negotiable.

Conversely, I’ve observed that natural fibres, derived from materials like cotton, wool, and coconut coir, bring an eco-conscious edge to spill management. Their biodegradability and lower environmental footprint often make them the go-to for operations that strive for sustainability, without compromising on absorption efficiency.

Biodegradability and Environmental Impact

During my tenure in spill management, I’ve become increasingly mindful of the long-term ramifications that the materials of an absorbent boom have on our environment. My preference often leans towards options that offer a strong balance between efficacy and environmental stewardship, considering how the disposed material will integrate or break down within the ecosystem.

The environmental impact remains a cornerstone of my decision-making process, as I strive to mitigate the footprint left behind by containment efforts. I champion the use of absorbent booms that excel in both performance and eco-friendliness, recognising that the right choice helps preserve delicate marine life and maintains the natural integrity of the spill site for future generations.

Compliance With Regulations and Standards

Ensuring that my spill containment methods adhere to existing standards is more than a formal requirement; it’s a moral imperative to protect our environment and comply with the law.

In selecting the ideal absorbent boom, I give full regard to local environmental protection standards, recognising that different regions have distinct ecological emphases and regulatory frameworks.

Equally, when assessing options for maritime and industry use, I diligently align my choices with the stringent regulations governing these sectors.

This conscientiousness in compliance safeguards not only the natural world but also the entities involved, promoting safe and responsible spill management practices.

Meeting Local Environmental Protection Standards

Adhering to local environmental protection standards is not only essential for legal compliance but also for ensuring community health and ecological safety. My selection of absorbent booms is always informed by local directives and the rigorous guidelines set forth by entities such as the United States Environmental Protection Agency, ensuring that every step I take is within the bounds of regulatory measures.

My commitment to these standards underpins the trust placed in my efforts to protect our environment from further harm. By meticulously choosing absorbent booms that meet, or even exceed, local regulations, I maintain a steadfast approach that prioritises the well-being of both nature and the communities impacted by spills.

Compliance With Maritime and Industry Regulations

I uphold a rigorous standard when integrating maritime and industry regulations into my selection process for oil spill absorbent booms. My tasks often bring me into compliance with international standards such as those mandated by the International Maritime Organization (IMO), which sets global requirements for oil pollution prevention and response.

To meet these industry-specific regulations, I actively seek absorbent booms that have been tested and proven in the field. In my day-to-day work, the materials and equipment I use not only have to perform well but must also adhere to the safety and environmental guidelines established by the oil and shipping industries.

Customization and Additional Features for Enhanced Performance

In determining the appropriateness of an oil spill absorbent boom for a specific situation, the capacity for customisation plays a crucial role in enhancing its overall performance.

I often find myself in scenarios where the standard off-the-shelf options simply won’t suffice — this is where the availability of added attachments and bespoke sizes truly makes a difference.

Through the years, I’ve learned that efficiency in spill response isn’t just about quick deployment but also about leveraging tailored solutions such as specialised attachments and adapting the dimensions of booms to meet the exact demands of the spill site, ensuring every aspect is covered with precise attention to detail.

Attachments and Accessories for Efficiency

In my professional experience, the efficacy of an oil spill response can be significantly amplified by the judicious use of attachments and accessories. The integration of absorbent sock connectors, for instance, allows me to shape booms to the specific contours of a spill site, enhancing containment by creating an uninterrupted barrier that’s custom-fitted to the environment.

Moreover, the strategic addition of anchoring systems and tensioners can vastly improve an oil spill boom’s performance. These components ensure that booms remain in place amid shifting currents and winds, offering me peace of mind that my containment efforts will remain robust and effective over time, regardless of changing conditions.

Custom Sizes and Lengths for Specific Needs

Addressing the exact scale and nature of an oil spill requires absorbent booms that align perfectly with the challenge at hand. My approach frequently involves commissioning custom-sized booms, a choice that allows for maximised efficiency and tailored containment, particularly in scenarios where space constraints or irregular spill patterns come into play.

Through years of stewarding spill responses, I’ve come to value the nuanced utility that custom lengths offer. By specifying booms to match the area of concern, I eliminate wasted materials and focus my attention on functional adaptability, ensuring that every inch contributes effectively to the containment and absorption process.

Conclusion

Selecting the ideal oil spill absorbent boom hinges on understanding the oil’s nature, spill volume, and the surrounding environment to ensure effective containment and cleanup.

The choice between natural and synthetic fibres for the boom’s construction balances performance with environmental impact and biodegradability.

In alignment with regulatory compliance from bodies such as the United States Environmental Protection Agency, one must choose a boom that adheres to industry standards while fulfilling local environmental protection criteria.

Customisation through attachments and exact sizing further refines the boom’s efficiency, proving versatile for specific spill scenarios and enhancing overall spill management efficacy.

As the winter doldrums begin to recede, spring marks a fresh start with its transition to better weather and new growth. But unfortunately, the change of season isn’t all about flowers and sunshine.

As the winter doldrums begin to recede, spring marks a fresh start with its transition to better weather and new growth. But unfortunately, the change of season isn’t all about flowers and sunshine.

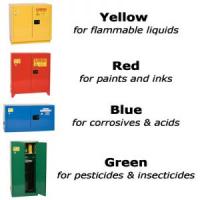

Did you know improper storage and handling of flammable liquids are significant contributors to industrial fires? According to research by the

Did you know improper storage and handling of flammable liquids are significant contributors to industrial fires? According to research by the

Do you have the right flammables safety products on hand for your workplace? To find out, contact Angie Meza at

Do you have the right flammables safety products on hand for your workplace? To find out, contact Angie Meza at

Have questions about which acid spill kits are right for your needs?

Have questions about which acid spill kits are right for your needs?