Water containment booms are floating barriers designed to contain or direct the flow of oil, debris, or other pollutants on water surfaces. These booms come in various types and sizes, each suited for specific environments and spill conditions. From small-scale spills in local water bodies to large-scale environmental disasters in oceans, the right boom can make a significant difference in spill control efforts. Whether you are dealing with oil spills in the ocean or debris on a river, choosing the right boom is the first step in effective spill management. A thorough understanding of the different types of booms and their applications is essential for anyone involved in spill response.

Types of Water Containment Booms

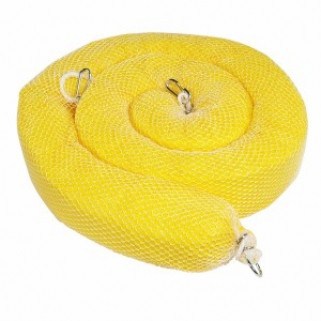

- Absorbent Booms: These are made from materials that can absorb oil and other contaminants. They are ideal for small spills and are often used in conjunction with other types of booms. Absorbent booms are particularly useful in confined spaces where spills are limited in size but require immediate attention. Their ability to soak up contaminants makes them a versatile tool in spill response kits.

- Non-absorbent Booms: Designed to contain but not absorb spills, these booms are used to redirect or contain larger spills until they can be cleaned up. They serve as a first line of defense, preventing the spread of contaminants over a wider area. Non-absorbent booms are often deployed in open waters where large spills pose significant environmental threats.

- Fire-resistant Booms: Used in scenarios where there is a risk of fire, these booms can withstand high temperatures. Their specialized materials prevent them from catching fire, making them suitable for high-risk environments. Fire-resistant booms are crucial in industrial areas where oil spills can quickly escalate into fire hazards.

- Permanent Booms: Installed in areas with frequent spills, these are durable and designed for long-term use. Permanent booms are often found in industrial zones or near offshore drilling sites, where the risk of regular spills is high. Their robust design and construction allow them to withstand harsh environmental conditions over time.

Importance of Regular Maintenance

Proper maintenance of water containment booms is crucial for ensuring they function effectively when needed. Without regular care, booms can deteriorate, reducing their ability to contain spills and increasing the risk of environmental damage. Regular inspections and maintenance can prevent minor issues from becoming major problems. By identifying potential issues early, you can extend the life of your booms and ensure they perform optimally when deployed.

Key Maintenance Practices

- Regular Cleaning: After use, booms should be cleaned thoroughly to remove any oil, debris, or chemicals. Use appropriate cleaning agents that do not damage the boom material. Regular cleaning prevents the buildup of contaminants that can degrade the boom’s integrity over time. Consistent cleaning practices also help maintain the boom’s buoyancy and effectiveness.

- Inspection for Damage: Regularly inspect booms for signs of wear and tear, such as tears, punctures, or degradation. Address any damage promptly to prevent it from worsening. Routine inspections can reveal subtle signs of wear that might otherwise go unnoticed. By maintaining a proactive inspection schedule, you can ensure your booms remain in good condition, ready for the next deployment.

- Hardware Check: Ensure that all connectors, chains, and other hardware components are in good condition. Replace any corroded or damaged parts immediately. Keeping hardware in top condition is essential for the secure deployment and retrieval of booms. Regular hardware checks can prevent failures that might compromise the boom’s effectiveness during a spill event.

- Absorbent Replacement: If using absorbent booms, replace the absorbent materials as needed to maintain effectiveness. Absorbents can become saturated and lose their ability to soak up contaminants, so timely replacement is crucial. Monitoring absorbent levels and having replacements on hand can make a significant difference in spill response efforts.

- Documentation: Keep records of maintenance activities, including inspections, repairs, and replacements. This documentation can be invaluable for tracking the lifespan and effectiveness of the booms. Detailed records allow you to monitor patterns in wear and tear, helping you plan for future maintenance needs. Documentation also provides accountability and transparency in spill response operations.

Proper Storage Techniques

Storing water containment booms correctly is just as important as maintaining them. Improper storage can lead to premature degradation, reducing the boom’s effectiveness and lifespan. Proper storage prolongs the life of the booms and ensures they are ready for use at a moment’s notice. By implementing effective storage strategies, you can protect your investment in these critical spill response tools.

Storage Best Practices

- Dry Storage: Always store booms in a dry environment to prevent mold, mildew, and other moisture-related damage. Moisture can weaken boom materials, making them less effective during deployment. Dry storage ensures that booms remain in optimal condition and ready for immediate use.

- Avoid Direct Sunlight: Prolonged exposure to UV rays can degrade the materials of the booms. Store them in a shaded area or use UV-resistant covers. UV damage can lead to brittleness and reduced flexibility, which can compromise the boom’s performance. Protecting booms from sunlight helps preserve their structural integrity.

- Proper Ventilation: Ensure storage areas are well-ventilated to prevent the buildup of fumes from any residual chemicals on the booms. Good ventilation helps maintain a safe storage environment, preventing chemical exposure to personnel. Ventilation also aids in the drying process after cleaning, reducing the risk of mold and mildew.

- Organized Storage: Store booms in a manner that allows for easy access and inventory management. Label different types and sizes clearly for quick identification. Organized storage facilitates rapid deployment during emergency situations, minimizing response times. Effective labeling and inventory management also help track boom usage and maintenance needs.

- Regular Checks: Even when not in use, regularly check stored booms for any signs of damage or degradation. Routine checks ensure that booms remain in good condition and ready for deployment. Regular monitoring also provides an opportunity to address any storage-related issues before they affect the boom’s performance.

Purchasing Absorbents Online

When it comes to maintaining your water containment booms, having a supply of absorbents on hand is essential. Absorbents play a crucial role in spill response, providing an additional layer of containment and cleanup capability. Purchasing absorbents online can be a convenient and efficient way to keep your stock replenished. By leveraging online resources, you can access a wide range of products and suppliers, ensuring you have the right absorbents for your needs.

Tips for Buying Absorbents Online

- Research Suppliers: Look for reputable suppliers who specialize in spill containment products. Check reviews and ratings to ensure quality and reliability. A reliable supplier can provide consistent product quality and customer support, essential for effective spill management.

- Understand Your Needs: Different spills require different absorbents. Know what types of spills you typically deal with and choose absorbents accordingly. Tailoring your absorbent purchases to your specific needs ensures you have the right tools for the job, enhancing your spill response capabilities.

- Compare Prices: Prices can vary significantly between suppliers. Take the time to compare and find the best deal without compromising on quality. Price comparison helps optimize your budget, allowing you to invest in other critical spill response resources.

- Check for Bulk Discounts: If you frequently need absorbents, buying in bulk can save you money. Many suppliers offer discounts for larger orders. Bulk purchasing not only reduces costs but also ensures you have a ready supply of absorbents for unexpected spill events.

- Read Product Descriptions: Ensure that the products meet your specific requirements by carefully reading descriptions and specifications. Understanding product features and limitations helps you make informed purchasing decisions, avoiding products that may not suit your needs.

Conclusion

Water containment booms are invaluable tools in spill management, and their maintenance and storage are key to their effectiveness. By following the practices outlined in this guide, you can ensure that your booms are always ready for action, providing reliable containment in the event of a spill. Regular maintenance, proper storage, and having the right absorbents on hand will not only extend the life of your booms but also enhance your overall spill response strategy. Whether you are a small business owner, an environmental manager, or part of an emergency response team, these tips will help you manage spills more efficiently and responsibly. Investing time in maintenance and storage not only safeguards your equipment but also contributes to a more sustainable and environmentally conscious approach to spill management.

Shop for Absorbents Online for Your Water Containment Booms

Ensure your spill response efforts are always ready by stocking up on high-quality absorbents. Visit Absorbents Online today to explore a wide range of absorbent products tailored for various spill scenarios. With competitive prices, bulk discounts, and reliable shipping, you can easily maintain your inventory and enhance your spill management strategy. Don’t wait for an emergency—shop now and be prepared for any situation!