Oil spills can be disastrous for the environment, impacting marine life, coastal communities, and ecosystems for years. In the quest to mitigate the damage caused by these incidents, synthetic sorbents have emerged as a key tool for oil containment and recovery. But just how effective are these materials in dealing with oil spills? This article delves into the science behind synthetic sorbents, their application in oil spill scenarios, and evaluates their efficacy.

Understanding Oil Spills and Their Impact

Oil spills occur when petroleum products are released into the environment, usually into the ocean or coastal areas, but they can also happen on land. These spills can be the result of accidents, such as tanker ship collisions or pipeline ruptures, or as a result of natural disasters that damage infrastructure.

The consequences of oil spills are severe and multifaceted. They can lead to:

- Environmental damage: Oil spills can poison marine and wildlife, destroy habitats, and disrupt ecosystems.

- Economic loss: The fishing and tourism industries often suffer greatly following a spill.

- Health issues: Exposure to oil and its fumes can cause health problems for humans and animals.

The Role of Synthetic Sorbents in Oil Spill Response

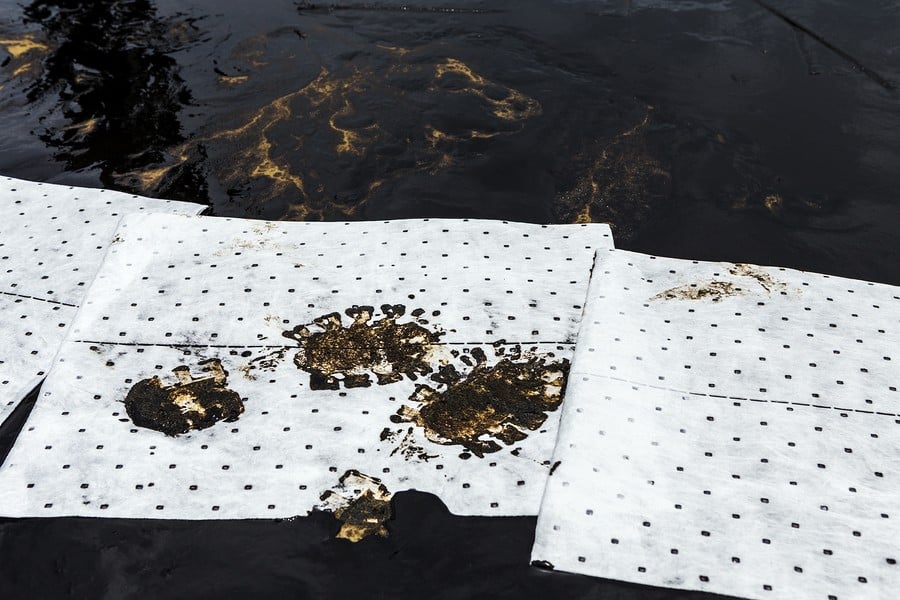

Synthetic sorbents are materials engineered to absorb liquids, with a particular affinity for oil. When introduced to an oil spill, these sorbents can absorb oil from the water, effectively removing it from the environment.

What Are Synthetic Sorbents?

Synthetic sorbents are typically made from man-made materials like polypropylene, polyester, or polyurethane. These materials are chosen for their hydrophobic (water-repelling) and oleophilic (oil-attracting) properties.

Advantages of Using Synthetic Sorbents

- High absorption rate: They can absorb many times their own weight in oil.

- Selective absorption: They tend to repel water while absorbing oil, making them ideal for oil spill cleanup.

- Reusability: Some synthetic sorbents can be squeezed out and reused, though this is dependent on the type of oil and the nature of the sorbent.

- Ease of deployment: They can be easily deployed in various forms, such as booms, pads, rolls, or loose fibers.

Limitations of Synthetic Sorbents

- Disposal issues: Once oil is absorbed, the sorbent becomes hazardous waste and must be disposed of properly.

- Environmental concerns: Some synthetic sorbents can break down into microplastics, which pose their own environmental risks.

- Cost: High-quality synthetic sorbents can be costly, which might limit their use in extensive spills.

Effectiveness of Synthetic Sorbents in Oil Spills

To evaluate the effectiveness of synthetic sorbents, it’s crucial to consider several factors, including the type of oil spilled, the conditions of the spill, and the specific characteristics of the sorbent used.

Absorption Capacity

Synthetic absorbents have a high absorption capacity, which is measured by the amount of oil they can absorb relative to their own weight. High-quality sorbents can absorb up to 70 times their weight in oil, making them extremely efficient.

Oil Containment

Sorbents are often used in conjunction with containment booms to prevent the spread of oil. While booms act as barriers, sorbents tackle the oil within the contained area. This combination can be a highly effective strategy for minimizing the spread of oil.

Speed of Response

The effectiveness of synthetic sorbents is also influenced by how quickly they can be deployed after a spill. The faster sorbents can be applied, the less opportunity there is for oil to spread or sink, making the cleanup operation more manageable.

Weather and Water Conditions

Rough seas, strong winds, and currents can all affect the performance of synthetic sorbents. While they are designed to withstand typical marine conditions, extreme weather can reduce their effectiveness.

Comparing Synthetic to Natural Sorbents

Natural sorbents, such as peat moss, straw, or cotton, are biodegradable alternatives to synthetic materials. While they have the advantage of being environmentally friendly, they generally absorb less oil and can be more difficult to deploy and recover than their synthetic counterparts.

Case Studies of Synthetic Sorbents in Action

Deepwater Horizon Oil Spill

The Deepwater Horizon oil spill in 2010 was one of the largest in history, releasing millions of barrels of oil into the Gulf of Mexico. Synthetic sorbents were used extensively in the response, and while they played a role in the cleanup, the sheer volume of oil overwhelmed all response methods.

Smaller-Scale Spills

In smaller spills, synthetic sorbents have proven to be much more effective. They can be quickly deployed and can greatly reduce the spread and impact of the oil, often with high recovery rates.

Innovations in Synthetic Sorbent Technology

Research is ongoing to develop new and improved synthetic sorbents that offer greater efficiency, environmental friendliness, and cost-effectiveness. Innovations include nanotechnology-based sorbents and biodegradable synthetics, which aim to address the limitations of current products.

Best Practices for Using Synthetic Sorbents

For optimal results, it’s important to follow best practices when using synthetic sorbents:

- Rapid deployment: Time is of the essence in oil spill response.

- Proper training: Responders should be well-trained in the use of sorbents.

- Appropriate disposal: Used sorbents must be disposed of according to environmental regulations.

- Monitoring: Regular assessment of the cleanup operation is crucial to adapt to changing conditions.

Conclusion

Synthetic sorbents are a valuable tool in the fight against oil spills. Their high absorption rates and ease of use make them effective in many scenarios, particularly when they are part of a well-coordinated response effort. While they are not without limitations, ongoing research and development promise to enhance their effectiveness and reduce their environmental impact. Ultimately, synthetic sorbents are a key part of a comprehensive strategy to protect our waterways and shorelines from the damaging effects of oil spills.

As we continue to rely on petroleum products, the risk of spills remains. Investing in the development and deployment of synthetic sorbents is not just a matter of cleanup—it’s an essential component of environmental stewardship and a commitment to safeguarding our planet’s future.

Call to Action

When it comes to managing oil spills and maintaining cleanliness in industrial settings, having the right absorbent materials is crucial. Shop at AbsorbentsOnline.Com for a comprehensive range of high-quality absorbents. Our selection includes a variety of synthetic sorbents designed to tackle spills efficiently and sustainably. Whether you need booms, pads, rolls, or loose fibers, AbsorbentsOnline.Com has the products and expertise to support your spill response efforts. Visit us today and ensure you’re prepared to handle any spill scenario with the best tools available.

Oil spills can be disastrous for the environment, impacting marine life, coastal communities, and ecosystems for years. In the quest to mitigate the damage caused by these incidents, synthetic sorbents have emerged as a key tool for oil containment and recovery. But just how effective are these materials in dealing with oil spills? This article delves into the science behind synthetic sorbents, their application in oil spill scenarios, and evaluates their efficacy.

Understanding Oil Spills and Their Impact

Oil spills occur when petroleum products are released into the environment, usually into the ocean or coastal areas, but they can also happen on land. These spills can be the result of accidents, such as tanker ship collisions or pipeline ruptures, or as a result of natural disasters that damage infrastructure.

The consequences of oil spills are severe and multifaceted. They can lead to:

- Environmental damage: Oil spills can poison marine and wildlife, destroy habitats, and disrupt ecosystems.

- Economic loss: The fishing and tourism industries often suffer greatly following a spill.

- Health issues: Exposure to oil and its fumes can cause health problems for humans and animals.

The Role of Synthetic Sorbents in Oil Spill Response

Synthetic sorbents are materials engineered to absorb liquids, with a particular affinity for oil. When introduced to an oil spill, these sorbents can absorb oil from the water, effectively removing it from the environment.

What Are Synthetic Sorbents?

Synthetic sorbents are typically made from man-made materials like polypropylene, polyester, or polyurethane. These materials are chosen for their hydrophobic (water-repelling) and oleophilic (oil-attracting) properties.

Advantages of Using Synthetic Sorbents

- High absorption rate: They can absorb many times their own weight in oil.

- Selective absorption: They tend to repel water while absorbing oil, making them ideal for oil spill cleanup.

- Reusability: Some synthetic sorbents can be squeezed out and reused, though this is dependent on the type of oil and the nature of the sorbent.

- Ease of deployment: They can be easily deployed in various forms, such as booms, pads, rolls, or loose fibers.

Limitations of Synthetic Sorbents

- Disposal issues: Once oil is absorbed, the sorbent becomes hazardous waste and must be disposed of properly.

- Environmental concerns: Some synthetic sorbents can break down into microplastics, which pose their own environmental risks.

- Cost: High-quality synthetic sorbents can be costly, which might limit their use in extensive spills.

Effectiveness of Synthetic Sorbents in Oil Spills

To evaluate the effectiveness of synthetic sorbents, it’s crucial to consider several factors, including the type of oil spilled, the conditions of the spill, and the specific characteristics of the sorbent used.

Absorption Capacity

Synthetic absorbents have a high absorption capacity, which is measured by the amount of oil they can absorb relative to their own weight. High-quality sorbents can absorb up to 70 times their weight in oil, making them extremely efficient.

Oil Containment

Sorbents are often used in conjunction with containment booms to prevent the spread of oil. While booms act as barriers, sorbents tackle the oil within the contained area. This combination can be a highly effective strategy for minimizing the spread of oil.

Speed of Response

The effectiveness of synthetic sorbents is also influenced by how quickly they can be deployed after a spill. The faster sorbents can be applied, the less opportunity there is for oil to spread or sink, making the cleanup operation more manageable.

Weather and Water Conditions

Rough seas, strong winds, and currents can all affect the performance of synthetic sorbents. While they are designed to withstand typical marine conditions, extreme weather can reduce their effectiveness.

Comparing Synthetic to Natural Sorbents

Natural sorbents, such as peat moss, straw, or cotton, are biodegradable alternatives to synthetic materials. While they have the advantage of being environmentally friendly, they generally absorb less oil and can be more difficult to deploy and recover than their synthetic counterparts.

Case Studies of Synthetic Sorbents in Action

Deepwater Horizon Oil Spill

The Deepwater Horizon oil spill in 2010 was one of the largest in history, releasing millions of barrels of oil into the Gulf of Mexico. Synthetic sorbents were used extensively in the response, and while they played a role in the cleanup, the sheer volume of oil overwhelmed all response methods.

Smaller-Scale Spills

In smaller spills, synthetic sorbents have proven to be much more effective. They can be quickly deployed and can greatly reduce the spread and impact of the oil, often with high recovery rates.

Innovations in Synthetic Sorbent Technology

Research is ongoing to develop new and improved synthetic sorbents that offer greater efficiency, environmental friendliness, and cost-effectiveness. Innovations include nanotechnology-based sorbents and biodegradable synthetics, which aim to address the limitations of current products.

Best Practices for Using Synthetic Sorbents

For optimal results, it’s important to follow best practices when using synthetic sorbents:

- Rapid deployment: Time is of the essence in oil spill response.

- Proper training: Responders should be well-trained in the use of sorbents.

- Appropriate disposal: Used sorbents must be disposed of according to environmental regulations.

- Monitoring: Regular assessment of the cleanup operation is crucial to adapt to changing conditions.

Conclusion

Synthetic sorbents are a valuable tool in the fight against oil spills. Their high absorption rates and ease of use make them effective in many scenarios, particularly when they are part of a well-coordinated response effort. While they are not without limitations, ongoing research and development promise to enhance their effectiveness and reduce their environmental impact. Ultimately, synthetic sorbents are a key part of a comprehensive strategy to protect our waterways and shorelines from the damaging effects of oil spills.

As we continue to rely on petroleum products, the risk of spills remains. Investing in the development and deployment of synthetic sorbents is not just a matter of cleanup—it’s an essential component of environmental stewardship and a commitment to safeguarding our planet’s future.

Call to Action

When it comes to managing oil spills and maintaining cleanliness in industrial settings, having the right absorbent materials is crucial. Shop at AbsorbentsOnline.Com for a comprehensive range of high-quality absorbents. Our selection includes a variety of synthetic sorbents designed to tackle spills efficiently and sustainably. Whether you need booms, pads, rolls, or loose fibers, AbsorbentsOnline.Com has the products and expertise to support your spill response efforts. Visit us today and ensure you’re prepared to handle any spill scenario with the best tools available.